Nikhil Gupta

,

FASM

-

Professor

Prof. Nikhil Gupta joined the NYU-Tandon School of Engineering faculty in 2004 and currently serves as Professor in the Department of Mechanical and Aerospace Engineering. He is also affiliated with the Department of Civil, Urban and Environmental Engineering and Center for Cybersecurity.

Prof. Gupta is an elected Fellow of ASM International and American Society for Composites and a Senior Member of IEEE. He is also an elected senior member of the National Academy of Inventors.

His other awards include the 2020 Brimacombe Medalist Award from TMS; 2013-ASM-International Silver Medal, 2013-TMS Young Leader Professional Development Award, 2007 and 2009 Visiting Lectureship Award from the American Society for Metals-Indian Institute of Metals, and the Air Force Summer Faculty Fellowship administered by the American Society of Engineering Education.

Prof. Gupta served as the Chair of the Composites Materials Committee of TMS (2016-2018) and Membership Secretary of American Society for Composites. He is serving on the editorial board of Materials Science and Engineering A and ASTM journal Materials Processing and Characterization and previously served on the editorial board of Composites Part B and Advanced Composites and Hybrid Materials.

Education

Malaviya National Institute of Technology, Jaipur 1996

Bachelor of Engineering, Metallurgical Engineering

Indian Institute of Science, 1998

Master of Engineering, Metallurgical Engineering

Louisiana State University, 2003

Doctor of Philosophy, Mechanical Engineering

Experience

NYU Tandon School of Engineering

Professor (2019- )

Associate Professor (2010-2019)

Assistant Professor (2004-2010)

Harvard University

Visiting Fellow (Fall 2022)

(On sabbatical from NYU)

Louisiana State University

Research Associate (2003-2004)

Research/Teaching Assistant (1999-2003)

Punjab Engineering College

Lecturer (1998-1999)

Publications

Journal Articles

Detailed publication list is available on Google Scholar

- Averardi, A., Cola, C., Zeltmann S. E. and Gupta, N. Effect of particle size distribution on the packing of powder beds: A critical discussion relevant to additive manufacturing. Materials Today Communications, 2020, 24, Paper # 100964.

- Chen, F., Yu, J. H. and Gupta, N. Obfuscation of Embedded Codes in Additive Manufactured Components for Product Authentication, Advanced Engineering Materials, 2019, # 1900146.

- Xu, X. and Gupta, N. Application of radial basis neural network to transform viscoelastic to elastic properties for materials with multiple thermal transitions. Journal of Materials Science, 2019, 54 (11), 8401–8413.

- Xu, X. and Gupta, N. Artificial neural network approach to predict the elastic modulus from dynamic mechanical analysis results. Advanced Theory and Simulations, 2019, 2 (4), 1800131.

Authored/Edited Books

- Poveda, R. L. and Gupta, N. Carbon Nanofiber Reinforced Polymer Composites, Springer, September 2015, ISBN 978-3-319-23786-2.

- Gupta, N., Pinisetty, D., Shunmugasamy, V. C. Reinforced Syntactic Foams: Effect of Nano and Micro-Scale Reinforcement, Springer, September 2013, ISBN 978-3-319-01242-1.

- Gupta, N. and Rohatgi, P. K. (Editors) Metal Matrix Syntactic Foams: Processing, Microstructure, Properties and Applications, DesTech Publications (May 2014).

Other Publications

- Rohatgi, P. K., Gupta, N. and Daoud, A. Synthesis and processing of cast metal matrix composites and their applications. ASM Handbook Vol. 15: Casting, 2008, pp. 1149-1164.

- Rohatgi, P. K., Schultz, B. F., Gupta, N. and Daoud, A. Solidification during casting of metal matrix composites. ASM Handbook Vol. 15: Casting, 2008, pp. 390-397.

Research

See research projects at composites lab site

Ongoing Research Projects

- Cybersecurity methods in additive manufacturing cyber-physical systems.

- Education of security in mechanical engineering curriculum.

- Fiber-optic sensor for wind turbine blade health monitoring.

- Machine learning methods in materials characterization.

Awards

-

Senior Member - National Academy of Inventors (Class of 2024)

-

Eminent Engineer Award, 2023, Institution of Engineers (India), Jaipur, India

-

Fellow - American Society for Composites, 2022

-

Fellow - ASM International (Class of 2022)

-

Senior Member - IEEE (Class of 2020)

-

Brimacombe Medalist Award 2020, TMS.

-

Silver Medal Award 2013, ASM-International.

-

Young Professional Development Award 2013, The Minerals, Metals, and Materials Society (TMS).

-

Featured on National Science Foundation Discoveries page: http://www.nsf.gov/discoveries/disc_summ.jsp?cntn_id=117761&org=NSF.

-

Featured on National Science Foundation News From The Field page: http://www.nsf.gov/news/news_summ.jsp?cntn_id=117510&org=ENG&from=newsField.

-

National Science Foundation Behind The Scene coverage: http://www.livescience.com/technology/bone-compression-injury-protective-gear-bts-100924.html.

-

Scientific American coverage and video: http://www.scientificamerican.com/blog/post.cfm?id=smashed-rabbit-bones-hint-at-hidden-2010-08-17.

-

American Society for Metals – Indian Institute of Metals (ASM-IIM) Visiting Lecturership Award 2007 and 2009.

-

Air Force Summer Faculty Fellowship, Wright-Patterson Air Force Base, 2009 (administered by the American Society for Engineering Education).

-

Junior Faculty Fellow, Othmer Institute of Interdisciplinary Studies, Polytechnic Institute of New York University, Brooklyn (2006-08).

Patents

- System and method for extruding composite filament. Nikhil Gupta, Ashish Singh, Brooks Salatonstall. US Patent #11,498,255 B2, Nov. 15, 2022.

- System and method for malware detection in additive manufactured parts. Michail Maniatakos, Nektarios Tsoutsos and Nikhil Gupta. US Patent #11,046,009 B2, 06/29/2021.

- Endoscope restraint, Nikhil Gupta, Farid Razavi. US Patent 11,013,395, Issued on 05/25/2021.

- Embedded security elements for digital models used in additive manufacturing. US Patent #10,872,177, Nikhil Gupta. 12/22/2020.

- Method to estimate strain rate dependent elastic modulus of materials using dynamic mechanical analysis data. US Patent #10,345,210, Nikhil Gupta, Steven Zeltmann. Issued on 07/09/2019.

- Nikhil Gupta, Nguyen Q. Nguyen, Fiber-optic extensometer. US Patent #8,428,400, April 23, 2013.

- Nikhil Gupta, Nguyen Q. Nguyen, Method for measuring the deformation of a specimen using a fiber optic extensometer. US Patent #8,649,638, February 11, 2014.

- Nikhil Gupta and Vasanth Chakravarthy Shunmugasamy, Multifunctional syntactic foams, US Patent US9676916, 2017.

Research News

Comprehensive study reviews best ways to monitor defects in additive manufacturing

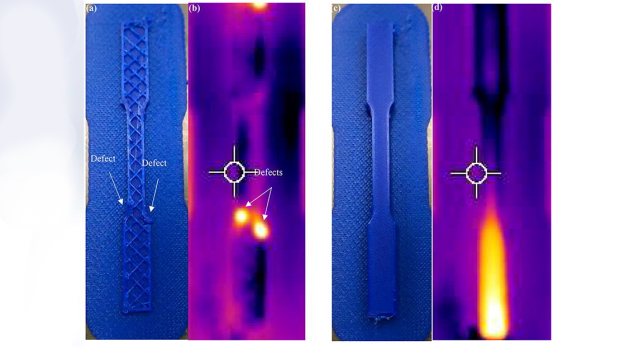

Additive Manufacturing (AM) — commonly known as 3D printing — involves manufacturing processes that depend on a user-defined set of optimized parameters. Monitoring and control of these processes in real-time can help achieve operational stability and repeatability to produce high-quality parts. By applying in-situ monitoring methods to AM procedures, defects in the printed parts can be detected.

In a new review in the Elsevier journal Materials & Design, Nikhil Gupta, professor of mechanical and aerospace engineering and director of the Composite Materials and Mechanics Laboratory at NYU Tandon, and Youssef AbouelNour, a doctoral student under Gupta’s guidance, examine the application of both imaging and acoustic methods for the detection of sub-surface and internal defects.

The imaging methods consist of visual and thermal monitoring techniques, such as optical cameras, infrared (IR) cameras, and X-ray imaging. The data is abundant as numerous studies have been conducted proving the reliability of imaging methods in monitoring the printing process and build area, as well as detecting defects.

Acoustic methods rely on acoustic sensing technologies and signal processing methods to acquire and analyze acoustic signals, respectively. Raw acoustic emission signals can correlate to particular defect mechanisms using methods of feature extraction. In their review, Gupta and AbouelNour discuss processing, representation and analysis of the acquired in-situ data from both imaging and acoustic methods. They also introduce ex-situ testing techniques as methods for verification of results gained from in-situ monitoring data.

Among their revelations:

- In-situ process monitoring methods can create a closed-loop AM process capable of defect correction and control, to ensure process stability and repeatability

- Integration of monitoring methods and machine learning in the AM process can help in continuously evaluating the quality of material deposition and developing intervention methods for correcting the defects in-situ

- And using x-ray Computed Tomography can lead to an in-depth evaluation of defects, as well as an assessment of the quality of in-situ monitoring methods.

- Integration of quality monitoring methods with the manufacturing methods eliminates the requirement to conduct the quality assessment separately, which can save a significant amount of time.

Separately, Gupta this year was honored as a Fellow of ASM International, a global organization of more than 20,000 members. The organization recognized Gupta for “pioneering contributions to the science and technology of lightweight polymer and metal matrix composites” and exceptional dedication to educating the public about scientific discoveries.

The work was supported by the Texas A&M Engineering Experiment Station and the National Science Foundation.

NYC Future Manufacturing Collective

Extensive use of sensors, computers and software tools in product design and manufacturing requires traditional manufacturing education to evolve for the new generation of cyber-manufacturing systems. While universities will continue to provide education to build a fundamental knowledge base for their students, the widening gap between the education delivered and the skills required by industry needs innovative solutions to prepare the workforce for future generations of manufacturing.

The New York City Future Manufacturing Collective (NYC-FMC) will develop a network of multidisciplinary researchers, educators, and stakeholders in New York City to explore future cyber manufacturing research through the lens of the worker's relationship to an increasingly complex and technologically driven environment and set of processes. The NYC-FMC will advance related technologies as well as the underlying systems, processes, and organizational conditions to which these interfaces are connected, to change and drive the roles of people in manufacturing.

NYC-FMC will organize a variety of activities, including an internship program for students to obtain exposure to industrial environments by engaging major manufacturing based corporations, producing a newsletter to define the state-of-the-art in manufacturing technologies and the new manufacturing ecosystem, and organizing two manufacturing-focused symposia each year. The program will build a coalition of multidisciplinary faculty from NYC universities, industry executives and technologists, investors, entrepreneurs, public sector and other relevant manufacturing ecosystem participants.

The NYC-FMC will take a convergence approach to generate novel ideas, frameworks, and hypotheses to catalyze future research, partnerships, and industrial innovation in manufacturing and cyber-physical systems. Executives and technologists from industry, including large manufacturing concerns with a connection to the greater NYC region and beyond and startup companies in the Brooklyn Navy Yard’s New Lab, will provide stimulus from the private sector and help create conditions to advance education and research goals. This coalition will build a novel education and workforce training program framework to create a learning and feedback loop between researchers, industry partners, and the workforce focused on the future cyber-manufacturing systems.

This award reflects NSF's statutory mission and has been deemed worthy of support through evaluation using the Foundation's intellectual merit and broader impacts review criteria.

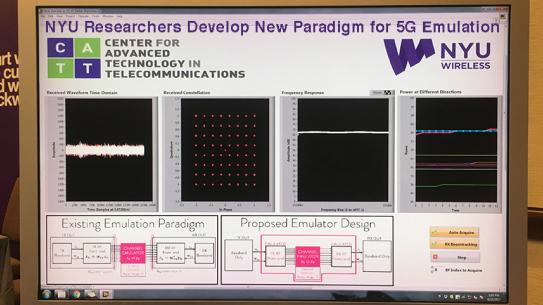

A survey of cybersecurity of digital manufacturing

This survey was led by Nikhil Gupta, professor mechanical and aerospace engineering and a member of the NYU Center for Cybersecurity; and Ramesh Karri, professor of electrical and computer engineering and co-founder and co-Chair of the NYU Center for Cybersecurity.

The Industry 4.0 concept promotes a digital manufacturing (DM) paradigm that can enhance quality and productivity, which reduces inventory and the lead time for delivering custom, batch-of-one products based on achieving convergence of additive, subtractive, and hybrid manufacturing machines, automation and robotic systems, sensors, com- puting, and communication networks, artificial intelligence, and big data. A DM system consists of embedded electronics, sensors, actuators, control software, and interconnectivity to enable the machines and the components within them to exchange data with other machines, components therein, the plant operators, the inventory managers, and customers.

Digitalization of manufacturing aided by advances in sensors, artificial intelligence, robotics, and networking technology is revolutionizing the traditional manufacturing industry by rethinking manufacturing as a service.

Concurrently, there is a shift in demand from high-volume manufacturing to batches-of-one, custom manufacturing of products. While the large manufacturing enterprises can reallocate resources and transform themselves to seize these opportunities, the medium-scale enterprises (MSEs) and small-scale enterprises with limited resources need to become federated and proactively deal with digitalization. Many MSEs essentially consist of general-purpose machines that give them the flexibility to execute a variety of process plans and workflows to create one-off products with complex shapes, textures, properties, and functionalities. One way the MSEs can stay relevant in the next-generation digital manufacturing (DM) environment is to become fully interconnected with other MSEs by using the digital thread and becoming part of a larger, cyber-manufacturing business network. This allows the MSEs to make their resources visible to the market and continue to serve as suppliers to OEMs and other parts of the manufacturing supply networks.

This article, whose authors include researchers from NYU Tandon and Texas A&M, explores the cybersecurity risks in the emerging DM context, assesses the impact on manufacturing, and identifies approaches to secure DM. It resents a hybrid-manufacturing cell, a building block of DM, and uses it to discuss vulnerabilities; discusses a taxonomy of threats for DM; explores attack case studies; surveys existing taxonomies in DM systems; and demonstrates how novel manufacturing-unique defenses can mitigate the attacks.

The team's research is supported, in part, by the National Science Foundation.

Tandon Team Leads NYC Future Manufacturing Collective

Nikhil Gupta, professor of mechanical and aerospace engineering is principal investigator on this project with Kurt Becker professor of applied physics and Vice Dean of Research Innovation, and Entrepreneurship; and Justin Hendrix, executive director of the NYC Media Lab at NYU Tandon.

Extensive use of sensors, computers and software tools in product design and manufacturing requires traditional manufacturing education to evolve for the new generation of cyber-manufacturing systems. However, with a widening gap between today's education and training curricula and the actual skills required by industry, innovative solutions are needed to prepare the workforce for the evolution of manufacturing.

The New York City Future Manufacturing Collective (NYC-FMC) will develop a network of multidisciplinary researchers, educators, and stakeholders in New York City to explore future cyber manufacturing research through the lens of the worker's relationship to an increasingly complex and technologically driven environment and set of processes. The NYC-FMC will:

- advance related technologies as well as the underlying systems, processes, and organizational conditions to which these interfaces are connected, to change and drive the roles of people in manufacturing.

- organize a variety of activities, including an internship program for students to obtain exposure to industrial environments by engaging major manufacturing based corporations, a newsletter to define the state-of-the-art in manufacturing technologies and the new manufacturing ecosystem, and two manufacturing-focused symposia each year.

- build a coalition of multidisciplinary faculty from NYC universities, industry executives and technologists, investors, entrepreneurs, public sector and other relevant manufacturing ecosystem participants.

The network will rely on faculty leadership at NYU and Columbia University, as well as a broad network of researchers from other NYC institutions, in the areas of manufacturing, computer vision, robotics, machine learning, virtual and augmented reality, human behavior and cognition, economics and other relevant areas. Executives and technologists from industry, including large manufacturing concerns with a connection to the greater NYC region and beyond and startup companies in the Brooklyn Navy Yard's New Lab, will provide stimulus from the private sector and help create conditions to advance education and research goals. This coalition will build a novel education and workforce training program framework to create a learning and feedback loop between researchers, industry partners, and the workforce focused on the future cyber-manufacturing systems.

The project, supported by a $500,000 Future Manufacturing grant from the National Science Foundation.