Building better buildings

A stroll around NYU Tandon will reveal an eclectic architectural landscape. From Wunsch Hall — once the site of the First Congregational Church and a pivotal stop on the Underground Railroad, and now home to admissions and career services — to the modern, renovated 370 Jay Street, the campus showcases a variety of building styles. This diversity mirrors the city's iconic skyscrapers, historic brownstones, and everyday residential buildings.

Throughout the years, NYU Tandon engineers have been foundational to the planning, construction and maintenance of the city’s buildings — one of many reasons that NYU is said to be not only in the city, but of it. And with buildings playing a vital role in ensuring more sustainable, resilient, liveable, and healthy cities (and most of us now spending an estimated 90% of our time indoors according to the U.S. EPA), our work is more important than ever.

According to code

In 1962 Polytechnic Institute was commissioned by New York City Mayor Robert Wagner to write the new building code for the city. The result was a 1,400-page, three-volume report that addressed numerous long-overdue issues, including fire protection, effective soundproofing, the novel use of pre-stressed and pre-cast concrete structural members, and new requirements for ramps or street-level entrances for access by people with disabilities.

The new code was enacted into law in 1968, with introductory text stating: “The purpose of this code is to provide reasonable minimum requirements and standards, based upon current scientific and engineering knowledge, experience and techniques, and the utilization of modern machinery, equipment, materials, and forms and methods of construction, for the regulation of building construction in the city of New York in the interest of public safety, health and welfare, and with due regard for building construction and maintenance costs.” All in all, quite the undersell for the immense positive impact it has had since then on building productivity, the reduction of environmental hazards, and overall safety.

Towering buildings, towering figures

Joseph J. Jacobs often fell asleep during his undergraduate classes, so exhausted was he from working an eight-hour shift as a short-order cook before school each day. Still, when Jacobs — the youngest of seven children born to parents who came to Brooklyn from Lebanon — graduated in 1937, he had made a good enough impression on his professors at what was then known as the Polytechnic Institute that he was offered a teaching fellowship — a real lifeline in those years of the Great Depression.

Jacobs went on to earn master’s and doctoral degrees, in 1939 and 1942, respectively, and in 1947 he founded an eponymous engineering, consulting, and construction firm that ultimately landed in the Fortune 500 and was once named by Forbes as one of the 100 most trustworthy companies in the country. The Jacobs Engineering Group now operates in more than 40 countries, has some 55,000 employees, and generates $13 billion in annual revenue: its founder’s portrait now hangs in the lobby of 6 MetroTech in testament to his generosity to his alma mater.

Another renowned alum, Charles H. Thornton (‘63, ‘66), was born in the Bronx with the building industry in his blood: his father, an electrician and bricklayer, served for a time as the borough’s chief building inspector.

After earning a master’s degree in civil engineering and a doctorate in structural mechanics from our university, Thornton went on to work at a company that counted several pavilions at the 1964 World’s Fair and a series of innovative 747 SuperBay hangars among its high-profile projects. He later became one of the founding principals of his own firm, Thornton Tomasetti, which quickly gained renown for such ambitious projects as the Petronas Towers in Malaysia and Taipei 101 in Taiwan (each at one time the tallest building in the world), 30 Hudson Yards in Manhattan, 1 Bennett Park in Chicago, the Wilshire Grand in Los Angeles, and Federation Tower in Moscow.

Although he was often called one of the most important structural engineers in the world, Thornton was as devoted to the nonprofit he founded as he was to his building projects. The ACE Mentor Program introduces high school students to potential careers in the Architecture, Construction and Engineering industries. Since its founding, in 1994, it has touched the lives of an estimated 10,000 students a year, including many here at Tandon.

As a young civil engineer in Egypt’s air force, Magued Iskander — now the Chair of Tandon’s Department of Civil and Urban Engineering — supervised the construction of roads, runways and reinforced concrete structures — as well as a beachfront recreational resort that included a house for President Hosni Mubarak.

Since then, he has gained a reputation as an expert in the analysis, design, and construction of deep foundations and as the leading authority in the use of recycled polymeric piling as a replacement for conventional piling, especially in waterfront environments. (Pile drivers, also known as hammers, are devices engineers use to install piles, or poles, into soils to support buildings, skyscrapers, and other structures with deep foundations.)

He is also renowned for the physical modeling of soil-structure interaction using transparent soils. Natural soils are opaque to visible light, so the only way to visualize internal deformations and flow paths is through X-rays, computerized tomography, or magnetic resonance imaging cameras. That equipment is expensive and difficult to use, particularly in educational settings, however, so transparent soils present a good solution.

The soils may be hard to see, but Iskander's contributions to the geotechnical field are apparent.

From undersea depths to urban heights

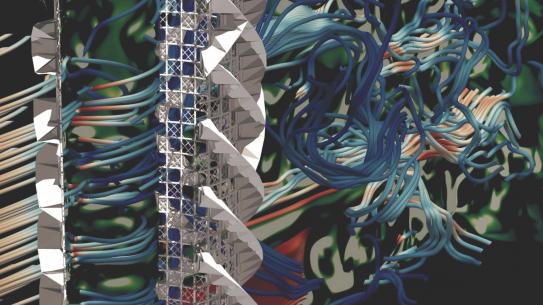

The Venus flower basket sponge, with its delicate glass-like lattice outer skeleton, has long intrigued researchers seeking to explain how this fragile-seeming creature’s body can withstand the harsh conditions of the deep sea where it lives. Now, a team of researchers co-led by Maurizio Porfiri, NYU Tandon Institute Professor and director of its Center for Urban Science + Progress (CUSP), has developed a highly realistic 3D replica of the sponge, containing around 100 billion individual points that recreate its complex helical ridge structure.

They discovered that the sponge’s unusual surface functions like a spiral staircase, allowing it to passively draw water upwards through its porous, lattice-like frame, all without the energy demands of pumping. The biomimetic engineering insights they gained through their research could one day lead to better air filtration and ventilation systems in skyscrapers and other structures.

Smart homes are getting smarter thanks to NYU Tandon

Sure, smart homes might incorporate buzz-worthy features like refrigerators that tell you when you’re out of milk or temperature controls that can be adjusted while you’re still at work, but Professor Nikhil Gupta, thinks they should be doing more.

Structural health monitoring (SHM) sensors — already being used on essential infrastructure like bridges and dams — could be tailored for residential use, he says, making smart homes even smarter by alerting residents to water damage, HVAC malfunctions, roof problems, and foundation issues before they become dangerous and costly to repair.

Innovative informatics

Why do some rooms make us feel anxious? How easy is it to navigate a certain type of stairwell? Biometric sensors and building information models may be able to tell us.

Tandon’s Building Informatics and Visualization Lab (biLAB), under the direction of Associate Professor Semiha Ergan, is dedicated to using cutting-edge technologies like AI and virtual reality to tackle many challenges in the design, construction, and operation of urban built environments.

In addition to tackling ways to make HVAC systems more energy efficient and providing technical support for energy-saving retrofits in buildings, biLAB researchers are currently addressing a fear many New Yorkers secretly harbor: being struck by a piece of falling building debris. Given the risks and inefficiencies involved in traditional methods of inspecting building facades, they’re developing an integrated 3D façade inspection platform that will eliminate reliance on manual expertise and better train machine-learning models to detect defects before anyone gets injured.

Robots to the rescue

The construction industry — which is estimated to be worth $1.6 trillion in the U.S. alone according to trade groups — is responsible for maintaining aging civil infrastructure and building new facilities that can accommodate the needs of the 21st century. The sector faces several issues, including the need to improve workplace safety, boost productivity, control costs, and alleviate labor shortages.

A promising technical solution is to introduce mobile robots on job sites, but construction robots face unique challenges due to the need to navigate dynamic environments, work closely with humans, and handle often heavy payloads. They are frequently limited in their performance by perception challenges due to occlusion and limited field of view.

In 2023 Assistant Professor Chen Feng of the Automation and Intelligence for Civil Engineering (AI4CE) lab, won a National Science Foundation CAREER Award that provided him with a five-year grant to further his fundamental research aimed at enabling better perception and navigation for the robots used to monitor construction job sites. He is currently creating an intelligent mobile robot team equipped with cameras and 3D LiDARs to autonomously monitor construction progress and operations to boost job site efficiency and safety.

In recent years, Chen — who sits on the board of the International Association of Automation and Robotics for Construction — has also designed autonomous systems for teams of 3D printers on robotic arms attached to mobile, roving platforms (advancing a concept called collective additive manufacturing), improved the efficiency and scalability of large-scale modular construction (a project he undertook with Ergan involving in-situ AR-robotic assistance), and explored the possibilities presented by particle robots (small, simplistic drones that can act together as a “swarm”), among other such projects.

Throughout his research, Chen breaks down departmental silos and melds robotics, artificial intelligence, and civil and mechanical engineering — an approach that allows him to contribute to advancements in not just robotics and AI, but multiple areas of great interest to urban planners and researchers, since construction is a major driver of growth in ever-evolving cities like New York.

Eco-friendly concrete solutions

With Chen on the collective additive manufacturing team was Industry Professor Weihua Jin, whose job was to develop new composite materials suitable for mobile 3D concrete printing. Among the innovations he has helped create are an ultra-low carbon and bendable concrete mix that has less than 2% portland cement by weight, meaning that its environmental impact is drastically reduced; concrete that includes waste glass as an aggregate; and concrete that actually captures CO2 and sequesters it within the material.

With concrete a popular choice for its durability, strength, and imperviousness to weather, his work is putting a new spin on a traditional building material.

Building the future of inspections

Annually, the United States spends over $42 billion on leak and moisture-related energy costs; the leaks are hard to find, and the current processes to locate them are intrusive, expensive, and a hazard to worker safety.

Alum Bilal Sher (‘22) is working to address that. His start-up, Building Diagnostic Robotics, as the name implies, leverages robotic technology and artificial intelligence to locate and identify damaging leaks and to provide a comprehensive evaluation of a building's physical condition, performance, and overall health.

The company had its genesis when Sher was a master’s student in Tandon’s AI4CE lab under the direction of Chen. His work there resulted in a prototype he and his team called EASEEBot, a drone capable of climbing up a building’s outer facade and flying over it to deploy digital and thermal cameras, thereby allowing it to identify air leaks, defects, and intrusions.

EASEEBot, which could work in confined spaces, allowing workers to stay out of hazardous areas, garnered a string of high-profile laurels, including a Civic Innovation Challenge award from the National Science Foundation (NSF) and the Department of Homeland Security, inclusion in the NYC Smart City Testbed Program, funding from NSF I-Corp, and an invitation to participate in NYU’s Tech Venture Accelerator.

Hyperspectral and hyper-useful

Hyperspectral imaging (produced by sensors that use a diffraction grating to spread incoming light out into its spectral components, analogous to how a prism breaks up a beam of white light into a rainbow) can help researchers studying the built environment distinguish between materials like stone and concrete that is just colored and finished to look like stone without the need to be directly on-site. Professor of Civil and Urban Engineering Debra Laefer, who is also affiliated with NYU’s Center for Urban Science + Progress (CUSP), recently collaborated with colleagues in Ireland to prove that this same technology can also identify different samples within a single type of material, such as concrete with a higher-than-recommended water content.

It thus becomes possible to identify weak materials in the building’s façade or piece of infrastructure without touching it — an important innovation given that most traditional materials-testing procedures require actually destroying samples.

The research is of great practical use to a wide variety of stakeholders, including building owners, developers, and preservationists, who may now have a new technique to quickly investigate the integrity of in-place construction materials and use that data to inform their respective activities.

Additionally, because hyperspectral imaging can be done from the air or from autonomous vehicles on a city-wide scale, public agencies may be able to conduct initial district-level inspections more rapidly and cost-effectively, all without erecting scaffolding or otherwise inconveniencing pedestrians. This can contribute significantly toward making a more efficiently run, livable urban environment.

By the book

When the 22,000-square-foot Hunters Point Community Library opened in 2019, it caused a major buzz. The New York Times called it “among the finest and most uplifting public buildings New York has produced so far this century” and a “crown jewel” among New York City’s public libraries.

The reporter wrote that the structure’s enormous windows “carve whimsical jigsaw puzzle pieces out of a cool, silvered-concrete facade. That facade is a load-bearing structure, allowing the library’s liberated interior to spiral some 60 feet upward and outward.”

That description gives little indication of the complexities of erecting such a facade, but alum Jorge Garcia (Civil Engineering, ‘13) has a firsthand perspective on the matter. He served in a dual role as the project’s General Superintendent and Senior Project Manager, meaning that he was in charge of all onsite operations involving subcontractor coordination, as well as the concrete structure, which was done by T.B. Penick, the company where he was then working

Garcia, who considers the library one of the most challenging projects of his career, credits the skills he learned at NYU Tandon as being pivotal to his success.

The next generation of civil engineers, urban planners, and construction managers

At Tandon, students have the chance to work on real-world projects so big and so important that they span several semesters, thanks to the Vertically Integrated Projects (VIP) program.

Multiple projects revolve around the built environment, allowing team members to put what they’ve learned in their classes to hands-on use.

One team, for example, supervised by Semiha Ergan, is leveraging augmented and virtual reality for Architecture, Engineering, Construction (AEC), and among their goals is to develop an AI assistant that can interact with workers to improve productivity inside factories manufacturing modular construction workpieces.

Another, the Seismic Design Competition Team, designs and constructs a model building capable of withstanding an earthquake. (The team takes part in an annual competition launched by the Earthquake Engineering Research Institute.) With the Federal Emergency Management Agency estimating that earthquake losses in the U.S. add up to more than $4 billion dollars a year and that around the world, some 20,000 people are killed annually when tectonic plates in the Earth’s crust shift, their work could one day save lives.