Developing Environmentally Friendly Processes and Polymer Products at Polytechnic

|

| The nation’s first Center for Biocatalysis and Bioprocessing of Macromolecules (NSF-BBM), established at Polytechnic University in 2000, was awarded a new five-year grant to continue its innovative research. Funded by the National Science Foundation (NSF) and private industry, the center conducts research to develop new “environmentally friendly” routes to polymers by using natural systems such as yeasts, fungi, bacteria and plants.

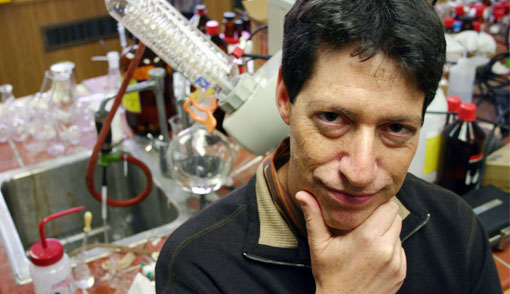

The NSF-BBM is using biocatalytic, or enzyme, reactions to connect small molecules known as monomers to form large molecules known as polymers. Instead of making polymers from potentially hazardous petroleum sources, renewable materials such as sugars and fatty acids are being transformed to make a family of naturally derived plastics. In another example, the center is replacing the use of heavy metal catalysts, which are toxic to the environment, with natural enzyme catalysts to produce high-volume commodity plastics. The center at Polytechnic is also developing new polyester families that will biodegrade upon disposal and has already created many new polymers by enzyme technology that provide an environmentally safe alternative to conventional chemical routes. The new enzymatic routes are resulting in products that can be used for coatings, adhesives, plastics, thickeners and gels. The new routes to products reduce energy consumption and the release of toxic chemicals during product manufacturing. Polytechnic University is working collaboratively with biomedical industry leaders and SUNY Downstate Medical Center to develop biocompatible polymers, polymeric drug-delivery systems and advanced therapeutic systems that actively promote wound healing and play a role in other biological processes. Recently, the NSF-BBM developed a new drug for the treatment of sepsis. The researchers’ findings, which appear in the January 2006 issue of Critical Care Medicine, show that the administration of sophorolipids significantly decreased mortality in animals with intra-abdominal induced sepsis. Dr. Richard A. Gross, the Herman F. Mark Professor of Polymer Science at Polytechnic and the center’s director, notes that the NSF Center for Biocatalysis and Bioprocessing of Macromolecules is creating private industry partnerships for technology development. “We believe such university/industry partnerships are critically needed in the United States to boost our competitive position,” he says, “since many private industries have severely reduced their budgets to do exploratory research. In addition, our students gain valuable insights into the realities of industry needs and expectations.” Gross was the 2003 Presidential Green Chemistry Challenge Award winner in the academic category for his contributions in environmentally friendly methods for synthesizing polymers. The NSF-BBM has two programs for private industry participation. The “core” program consists of cooperative research, whereby companies pool their financial investment in the center to gain access to a larger research program. Companies that have more specific research needs may elect the “non-core” program, where research is carried out directly between one company and the NSF-BBM center at Polytechnic University. Chemical and biomedical industry leaders that have partnered with the center include BASF, Rohm & Hass, DNA2.0, Grace Chemical Co., Novozymes, Genencor, Estee Lauder and Johnson & Johnson. Dr. Paolo Giacomoni, executive director of research for Estee Lauder Companies, says the production of polymers using enzymes is natural and safe. “It is the method of choice to prepare polymers for cosmetic products,” he explains, “and we look forward with optimism at its application in the very near future.” Another member of the NSF-BBM private industry consortium is the Advanced Biosciences Business of Rohm and Haas Company. “We have enjoyed a very direct form of collaboration with Dr. Gross and the laboratory at Polytechnic,” says M. Elizabeth Miller, senior scientist, Rohm and Haas Company. “Through our collaborative efforts we have learned more about the properties required of polymeric resins for their optimal use as solid supports for immobilized enzymes.” Dr. Kalle Levon, director of Polytechnic’s Polymer Research Institute, said: “The NSF-BBM is helping Polytechnic move ahead and further develop activities that integrate biology, chemistry and engineering disciplines. The center continues to enhance our national reputation for being in the forefront of polymer science.” |