Watch: André Taylor discusses his research on Perovskite Solar Cells with Hari Sreenivasan on scitech now

Publications

Journal Articles

F. Antonio, M. Beromi, T. Goh, N. Hazari, J. Kong, M. Mariano, and A.D. Taylor (2017). Colorful polymer solar cells employing an energy transfer dye molecule, Nano Energy, 38, 36-42.

T. Goh, D. Huang, T. Goh, J. Kong, A.D. Taylor, Z. Xu, S. Zhou, and Y. Zheng (2017). Perovskite solar cells with a DMSO-treated PEDOT:PSS hole transport layer exhibit higher photovoltaic performance and enhanced durability, Nanoscale, 9, 4236-4243.

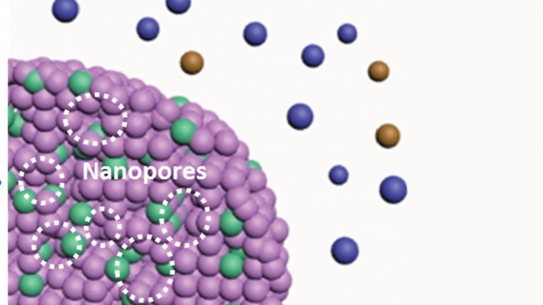

G. Doubek, R.C. Sekol, J. Li, E. Moy, S. Nejati, W-H. Ryu, C. Reid, M. Carmo, M. Linardi, E. Kinser, Y. Liu, C.O. Osuji, J. Schroers, S. Mukherjee, and A.D. Taylor (2016), Guided Evolution of Bulk Metallic Glass Nanostructures: A Platform for Designing Three-Dimensional Bicontinuous Electrocatalytic Surfaces, Advanced Materials, accepted

F.S. Gittleson, D. Hwang, W-H Ryu, S. Hashmi, J. Hwang, T. Goh, and A.D. Taylor (2015), Ultrathin Nanotube/Nanowire Electrodes by Spin-Spray Layer-by-Layer Assembly: A Concept for Transparent Energy Storage, ACS Nano, 9 (10), 10005-10017.

F.S. Gittleson, K.P.C. Yao, D.G. Kwabi, S.Y. Sayed, W-H. Ryu, Y. Shao-Horn, and A.D. Taylor (2015), Raman Spectroscopy in Lithium-Oxygen Battery Systems, ChemElectroChem (Invited Mini Review for Special Issue; Very Important Paper), 2 (10), 1426-1426.

W.H. Ryu, F.S. Gittleson, M. Schwab, T. Goh, A.D. Taylor (2015), A Mesoporous Catalytic Membrane Architecture for Lithium-Oxygen Battery Systems, Nano Letters, 15, 434-441.

T. Goh, J-S. Huang, E. Bielinski, B. Thompson, S. Tomasulo, M. Lee, M. Sfeir, N. Hazari, and A.D. Taylor (2015), Co-evaporated Bi-squaraine Inverted Solar Cells: Enhancement Due to Energy Transfer and Open Circuit Voltage Control, ACS Photonics, 2 (1), 86-95.

X. Li, L.M. Guard, J. Jiang, K. Sakimoto, J.-S. Huang, J. Wu, J. Li, L. Yu, R. Pokhrel, G.W. Brudvig, S. Ismail-Beigi, N. Hazari and A.D. Taylor (2014), Controlled doping of carbon nanotubes with metallocenes for application in hybrid carbon nanotube/Si solar cells, Nano Letters, 14 (6), 3388–3394.

J-S. Huang, T. Goh, X. Li, M. Sfeir, E. Bielinski, S. Tomasulo, M. Lee, N. Hazari, and A.D. Taylor (2013), Polymer bulk heterojunction solar cells employing Föerster resonance energy transfer, Nature Photonics, 7, 479–485.

X. Li, Y. Jung, K. Sakimoto, T. Goh, M.A. Reed, and A.D. Taylor (2013), A Systematic Study for High Efficiency Single Walled Carbon Nanotube/Silicon Hybrid Solar Cells, Energy and Environmental Science, 6, 879-887.

R.C. Sekol, G. Kumar, M. Carmo, F.S. Gittleson, N. Hardesty-Dyck, S. Mukherjee, J. Schroers, and A.D. Taylor (2013), Bulk Metallic Glass Micro Fuel Cell, SMALL, 9 (12), 2081-2085.

M. Carmo, R.C. Sekol, S. Ding, G. Kumar, J. Schroers, and A.D. Taylor (2011), Bulk Metallic Glass Nanowires Architecture for Electrochemical Applications, ACS Nano, Vol. 5, No. 4, 2979-2983.

Awards

- Dr. Martin Luther King, Jr. Visiting Associate Professor, MIT, Cambridge, MA. (2014-2015)

- PECASE - Presidential Early Career Award for Scientists and Engineers (2011)

- Yale Greer Memorial Prize (2011)

- NSF CAREER Award (2010-2015)

Information for Mentees

I've been at Tandon since 2018, prior was at Yale (1st tenured AA in the history of the Yale School of Engineering and Applied Science), enjoy helping people win, prefer informal interactions but can adjust to the needs of the mentee.

My Science: Energy Devices, Nanostructured Materials, Organic Solar Cells

Research News

Electric pulse method yields precisely tuned metallic glass nanoparticles

Researchers at NYU Tandon have developed a new method for synthesizing metallic glass nanoparticles that offers refined control over size, composition, and atomic structure — features long sought in the design of advanced catalytic materials used in chemical reactions key to advancements in sustainability and other fields.

In the paper "Metallic Glass Nanoparticles Synthesized via Flash Joule Heating" published in ACS Nano, a team led by André D. Taylor, Professor of Chemical and Biomolecular Engineering, describes how a technique known as flash Joule heating can rapidly produce amorphous palladium-based nanoparticles with reproducible and tunable features.

Metallic glasses are non-crystalline metals with unique properties, such as enhanced corrosion resistance and catalytic activity. Yet producing them in nanoparticle form with specific characteristics has posed difficulties, especially when it comes to controlling cooling rates during production.

The team’s method involves sending an electrical pulse through a precursor material, heating it rapidly and then allowing it to cool at a controlled rate. This process yields metallic glass nanoparticles with consistent sizes — averaging about 2.33 nanometers — and tailored alloy compositions. Among the nanoparticles produced were Pd-P, Pd-Ni-P, and Pd-Cu-P systems.

“Flash Joule heating gives us a way to fine-tune the synthesis process and isolate the effects of phase and composition,” said Taylor. “This makes it easier to examine the structure-property relationship in metallic glass systems, especially for applications like electrocatalysis.”

To evaluate performance, the researchers tested the amorphous nanoparticles as electrocatalysts for the oxygen evolution reaction (OER) — a critical step in electrochemical water splitting. They found that the metallic glass nanoparticles exhibited significantly lower onset potentials, by around 300 millivolts, compared to their crystalline counterparts. The materials also demonstrated stable catalytic behavior over extended operation times of up to 60 hours.

"Metallic glass has been a focus of research in our lab for many years, and this flash Joule heating methodology represents a significant step forward in our ability to synthesize these materials with precision," said Hang Wang (Ph.D. '24), the paper's lead author and a Ph.D. candidate in Taylor's lab at the time of the research." What's particularly exciting is how this approach could eventually scale beyond laboratory settings. Unlike other nanomaterial synthesis methods that remain confined to small batches, this technique has the potential to bridge the gap between research and real-world implementation in energy applications."

The study provides a new approach to systematically exploring amorphous alloy systems at the nanoscale and may support ongoing efforts in energy storage, catalysis, and electronic materials development. While the work focuses on palladium-based systems, the method could be adapted for other alloy systems that benefit from amorphous structures.

Besides Taylor, other contributors to this paper include Hang Wang, Nathan Makowski, Yuanyuan MaXue Fan, Stephen A. Maclean, Jason Lipton, Juan Meng, Jason A. Röhr, and Mo Li. This research was primarily supported by the U.S. Department of Energy.

Metallic Glass Nanoparticles Synthesized via Flash Joule Heating. Hang Wang, Nathan Makowski, Yuanyuan Ma, Xue Fan, Stephen A. Maclean, Jason Lipton, Juan Meng, Jason A. Röhr, Mo Li, and André D. Taylor; ACS Nano 2025 19 (21), 19806-19817 DOI: 10.1021/acsnano.5c02173

Novel technique boosts cadmium telluride solar cell performance by 13 percent

An NYU Tandon-led research team has developed a novel technique to significantly enhance the performance of cadmium telluride (CdTe) solar cells. Unlike conventional silicon panels that use thick layers of silicon, these solar cells use a simpler, less expensive approach — depositing an ultra-thin layer of cadmium and tellurium compounds onto glass.

This thinner design reduces manufacturing costs while helping the cells maintain their efficiency at high temperatures and in low-light conditions. Though less common than traditional silicon panels — the familiar dark blue or black panels seen on rooftops — CdTe solar cells are an emerging technology primarily used in utility-scale solar farms, currently accounting for about 40% of U.S. large-scale solar installations.

A persistent challenge with these cells, however, has been damage that occurs during a critical manufacturing step — when the metal wiring is added to collect electricity from the cell. The high-temperature process of applying these metal contacts can damage the material, particularly at the boundaries where microscopic crystal regions meet, like weak points between tiles in a mosaic. This damage creates barriers that reduce the cell's power output.

In research published in ACS Applied Materials & Interfaces, the team found that applying an ultra-thin oxide coating — either aluminum gallium oxide (AlGaOx) or silicon oxide (SiOx) — before adding metal contacts like gold prevents this damage. The coating naturally collects at these vulnerable boundaries between crystal regions, protecting them while leaving the rest of the surface clear for electrical contact.

This simple and scalable solution has led to major improvements in the cells' electrical output, increasing the maximum voltage they can produce by 13% and boosting their overall power generation.

"Silicon solar cells are rated at room temperature, but their performance drops as temperatures rise. You don't have that problem with CdTe cells, which makes them particularly valuable in warmer regions like the Caribbean or near the equator," said André Taylor, an NYU Tandon professor of chemical and biomolecular engineering and one of the paper’s authors. The paper’s corresponding author is B. Edward Sartor, who was a doctoral student in Taylor's lab when the study was conducted.

With the protective layer in place, the open-circuit voltage of the solar cells increased from 750 to 850 millivolts. The fill factor, another key efficiency metric, also improved, provided the oxide layer remained thin enough to avoid increasing electrical resistance.

"The AlGaOx layer protects the cell when you're evaporating the gold contacts, which come in at high temperature and condense on the surface. Without this protection, you damage the interface and create defects that lower device performance," Taylor explained.

The oxide layer is applied through a simple spin-coating process, a widely used technique in semiconductor manufacturing that allows precise control over coverage. The researchers also found that the method works with different metal contacts, including gold and molybdenum, and that it shows potential benefits when combined with zinc telluride nitrogen-doped (ZnTe:N) buffer layers, which help facilitate the movement of positive charge carriers (holes) in the solar cell.

"This discovery suggests a promising path to make CdTe solar cells more efficient and reliable,” said Taylor. “It's a straightforward adjustment to existing manufacturing processes that could potentially advance solar energy production."

The research comes at a critical time for U.S. solar manufacturing. After losing the silicon solar cell market to China, CdTe technology offers a strategic opportunity to rebuild domestic manufacturing capabilities, with companies like First Solar leading the way. The technology also offers a unique sustainability angle: tellurium, a key ingredient, can be extracted from copper mining operations, where it was previously considered a waste material, potentially creating new economic value.

Funded by the U.S. Department of Energy's Solar Energy Technologies Office, this research adds to Taylor's diverse solar technology portfolio. His research group has explored multiple solar cell technologies, including polymers, small molecule solar cells, and hybrid cells combining carbon nanotubes with silicon. The group previously introduced the world's first Förster Resonance Energy Transfer (FRET)-based solar cell and continues to advance research in emerging technologies like perovskite solar cells.

Sartor, B. E., Muzzio, R., Jiang, C.-S., Lee, C., Perkins, C. L., Taylor, A. D., & Reese, M. O. (2025). Selective Isolation of Surface Grain Boundaries by Oxide Dielectrics Improves Cd(Se,Te) Device Performance. ACS Applied Materials & Interfaces, 17(5), 7641–7647. doi:10.1021/acsami.4c16902

Correlating wavelength dependence in LiMn2O4 cathode photo-accelerated fast charging with deformations in local structure

Electric vehicles are one of the best tools we currently have to combat the effects of climate change. There is one outstanding problem though: it takes a significant amount of time to charge a vehicle. Even fasting-charging units take much longer to “fill up” an EV than do gas pumps to fill a tank. This may seem like a mere annoyance, but for people pressed for time this is no small acceptance hurdle between internal combustion and EVs.

There have been numerous efforts at the material-level to improve charging rates through engineered electrode coatings and nanostructuring of active materials, which limit energy density in the battery pack. Additionally, the study of light interaction with energy storage materials has gained interest for use in photo-rechargeable batteries, and integrated solar energy storage systems, though there have been few studies specifically investigating light interaction with commercially-relevant battery materials. Facilitation of electron movement in a battery material is a key for lowering the resistance to flow of charge. Administration of light to induce light-matter interactions is a possibility to locally alter the electronic nature of the material. In particular, Spinel LiMn2O4 (LMO), a cathode material, was shown to dramatically increase the charging current when exposed to white light during a voltage hold.

Now, a team of researchers led by André D. Taylor, professor of Chemical and Biomolecular Engineering and member of the Sustainable Engineering Initiative, as well as graduated PhD student Jason Lipton and Christopher Johnson of the Argonne National Laboratory, have discovered how different wavelengths of light can change the current in LMO cathodes. The team showed that illuminating with red light results in a higher charging rate compared to both ultraviolet illumination of equal optical power and dark conditions.

The team analyzed the effect of red light in the context of the electronic structure and possible excitations, and showed that Mn d-d electronic transitions occurring under red light illumination are largely responsible for the increased charging rate. They further demonstrated through X-ray absorption spectroscopy methods that LMO Mn-Mn bond distances shorten after d-electron excitation. The shrinkage in the crystal volume beneficially contributes to delithiation kinetics by lowering the resistance to lithium-ion conduction.

The results provide a roadmap for rapid discovery of candidate materials for photo-accelerated fast charging, through the review of calculated density of states data. Besides LMO, there is a wealth of materials to investigate with strong potential for photo-electrochemically induced activity. Once photo-acceleration is optimized for a given materials system, it is possible to envision using a small amount of the source current from a fast-charging station to power thin, flexible LEDs built into the spiral wound 18650 cells in a battery pack, enhancing the fast-charging capabilities in next-generation EVs while minimizing impact to energy density.

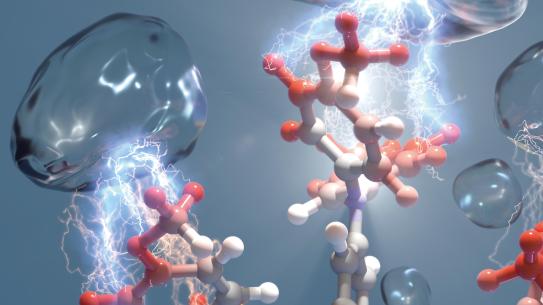

CO2 doping of organic interlayers for perovskite solar cells

The team reporting on this research was led by André D. Taylor, a professor of chemical and biomolecular engineering at NYU Tandon, and post-doctoral associate Jaemin Kong.

Perovskite solar cells have progressed in recent years with rapid increases in power conversion efficiency (from 3% in 2006 to 25.5% today), making them more competitive with silicon-based photovoltaic cells. However, a number of challenges remain before they can become a competitive commercial technology.

One of these challenges involves inherent limitations in the process of p-type doping of organic hole-transporting materials within the photovoltaic cells.

This process, wherein doping is achieved by the ingress and diffusion of oxygen into hole transport layers, is time intensive (several hours to a day), making commercial mass production of perovskite solar cells impractical. The Tandon team, however, discovered a method of vastly increasing the speed of this process through the use of carbon dioxide instead of oxygen.

In perovskite solar cells, doped organic semiconductors are normally required as charge-extraction interlayers situated between the photoactive perovskite layer and the electrodes. The conventional means of doping these interlayers involves the addition of lithium bis(trifluoromethane)sulfonimide (LiTFSI), a lithium salt, to spiro-OMeTAD, a π-conjugated organic semiconductor widely used for a hole-transporting material in perovskite solar cells, and the doping process is then initiated by exposing spiro-OMeTAD:LiTFSI blend films to air and light. Besides being time consuming, this method largely depends on ambient conditions. By contrast, Taylor and his team reported a fast and reproducible doping method that involves bubbling a spiro-OMeTAD:LiTFSI solution with carbon dioxide (CO2) under ultraviolet light.

They found that the CO2 bubbling process rapidly enhanced electrical conductivity of the interlayer by 100 times compared to that of a pristine blend film, which is also approximately 10 times higher than that obtained from an oxygen bubbling process. The CO2 treated film also resulted in stable, high-efficiency perovskite solar cells without any post-treatments.

The lead author Jaemin Kong explained that “Employing the pre-doped spiro-OMeTAD to perovskite solar cells shortens the device fabrication and processing time. Further, it makes cells much more stable as most detrimental lithium ions in spiro-OMeTAD:LiTFSI solution were stabilized to lithium carbonate, created while the doping of spiro-OMeTAD happened during CO2 bubbling process. The lithium carbonates end up being filtered out when we spincast the pre-doped solution onto the perovskite layer. Thus, we could obtain fairly pure doped organic materials for efficient hole transporting layers.”

Moreover, the team found that the CO2 doping method can be used for p-type doping of other π-conjugated polymers, such as PTAA, MEH-PPV, P3HT, and PBDB-T. Taylor said the team is looking to push the boundary beyond typical organic semiconductors used for solar cells.

"We believe that wide applicability of CO2 doping to various π-conjugated organic molecules stimulates research ranging from organic solar cells to OLEDs and OFETs even to thermoelectric devices that all require controlled doping of organic semiconductors,” and added that “Since this process consumes a quite large amount of CO2 gas during the process, it can be also considered for CO2 capture and sequestration study in the future. We are hoping that the CO2 doping technique could be a stepping stone for overcoming existing challenges in organic electronics and beyond.”