Diagnostic companies triumph at the Stern $300K Entrepreneurs Challenge

When the Stern $300K Entrepreneurs Challenge culminated on May 10, two teams with Tandon members garnered top honors in the Technology Venture portion of the annual event, which is hosted by the W. R. Berkley Innovation Labs. One of the most hotly contested startup competitions in the world, the Challenge drew almost 250 teams comprising more than 500 students, faculty and alumni from 19 schools across NYU’s global network.

Teams had spent a demanding eight months attending workshops, boot camps, and one-on-one coaching sessions designed to guide them through the startup process, from ideation to product launch, and at the end, after a final pitch to judges, Blue Instrument and MICSI were declared winners and awarded a share of the $100K Tech Venture prize. (Other winners shared the New Venture and Social Venture prizes.)

Not tilting at windmills

Blue Instrument — founded by Tandon Ph.D. candidate Yi Yang, who serves as CEO; M.S. student Skandh Garg, the startup’s CIO; and Associate Professor of Mechanical and Aerospace Engineering Nikhil Gupta, the team’s technical lead — took home $40K for their fiber-optic sensing system, which detects damage such as cracks in the wind turbine blades.

Made from a loop of thin optical fiber and a fixed wavelength laser, the system helps wind-farm operators to identify problems in real time, lessening the chance that they will lead to catastrophic failure and greatly reducing the costs of maintenance, since, as with other wind-turbine equipment, detecting cracks and problems early enough makes repairs less expensive. Along with gearboxes, turbine blades have always generated among the most costly repairs faced by operators, the team has explained, and a blade can break and fall if a growing fracture is undetected long enough.

Additional savings are realized because the Blue Instrument system costs less to install than other monitoring technologies and requires little training to operate, making it exponentially less expensive than ground-based visual, manual, or drone inspections.

While the team plans initially to retrofit working turbines with the sensors (with no shortage of operators approaching during the customer discovery phase of the Blue Instrument launch), Gupta, Yang, and Garg, eventually hope that manufacturers will embed the sensors during production.

High-end quality on low-end MRI scanners

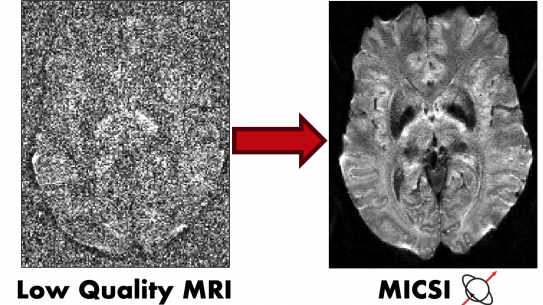

MICSI (Microstructure Imaging, INC) — founded by Tandon Ph.D. candidate Benjamin Ades-aron and School of Medicine Ph.D. graduate Gregory Lemberskiy — is focused on improving signal-to-noise ratio, a key performance metric of magnetic resonance imaging (MRI). (If you reduce the noise, the improvement in signal-to-noise ratio can be used to increase the image resolution and/or decrease the scan time.)

They are doing so with proprietary software — a much more affordable option for hospitals or other healthcare facilities, which often can’t afford the many millions of dollars a high-end MRI scanner would cost.

During an MRI scan, a strong magnetic field is used to align atomic spins in a particular direction, and radio-waves are then applied to perturb these spins away from equilibrium. Various combinations of radio pulses and smaller magnetic field gradients are used to encode the spins with imaging contrasts and used to generate a multitude of images, which can be related to inflammation, tissue density, and even “thought-related” neuronal activity. The image quality is closely related to the strength of the magnetic field measured in Teslas (T), with the vast majority of scanners purchased ranked as 1.5 T and selling for approximately $1.5 million.

“A scan from a 1.5T machine, when run through our software, is comparable to that taken by a 3T machine, which costs in the vicinity of $3 million,” Ades-aron explains. “And not only is there a savings in upfront equipment costs, but because scan time is reduced, the number of patients who can be seen each day increases, which also represents a savings.”

Of course, he points out, much more is at stake than the bottom line: as image quality is enhanced, so too is the likelihood that the scan can be used to make an accurate diagnosis.

During customer discovery the team found a niche apt to be unfamiliar to laypeople: neurosurgeons who perform what is known as “awake craniotomies,” operations performed in the same manner as conventional craniotomies but with the patient awake, thus allowing medical personnel to test regions of the brain for function as tumors are removed. “A high-quality scan can show functional regions in minute detail before surgeons even make an incision,” Ades-aron says. “We look forward to seeing the day that we can look back on awake craniotomy as an archaic medical practice, similar to exploratory surgeries.”

An online prototype of the software is currently available and is being used for proof-of-concept, and the founders hope to win FDA approval in the coming months — a process that will be aided by their $60K Entrepreneurs Challenge win. “After approval we’ll scale up,” Ades-aron predicts, “and we’re looking forward to our technology being available to hospitals across the country.”