Asphalt is special ingredient in electrode material for long-life sodium-ion batteries

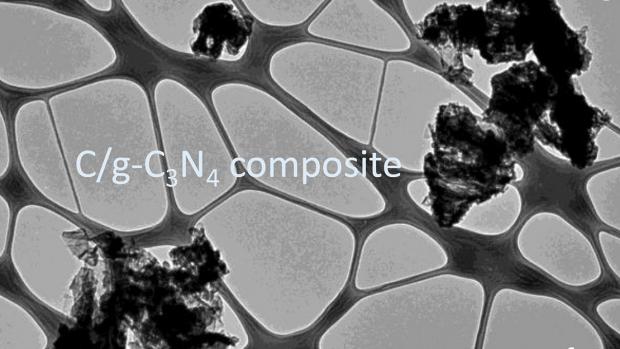

Micrograph of 2D graphitic carbon nitride material, developed by researchers at NYU Tandon, that could be a game-changer for sodium-ion battery electrodes

BROOKLYN, New York, Wednesday, September 4, 2019 – Rechargeable sodium-ion batteries, based on low-cost, abundant, easily processed, and non-toxic materials, could constitute a cost-effective and greener alternative to high-cost lithium-ion batteries, enabling the proliferation of a new generation of energy storage devices for everything from smart phones to wind farms and electrical grids.

A major hurdle to the adoption of sodium-ion batteries is that graphite electrodes, necessary components that function well in a lithium-ion environment, are unstable in sodium, resulting in low-efficiency, low-energy-density sodium-ion batteries.

An NYU Tandon research team led by Andre Taylor, professor of chemical and biomolecular engineering, and postdoctoral associate Dr. Guo-Ming Weng developed a stable negative electrode material for sodium-ion batteries by an alteration that carries the side benefit of finding a useful home for a waste byproduct of oil refining: asphalt. The study, “A Promising Carbon/g‐C3N4 Composite Negative Electrode for a Long‐Life Sodium‐Ion Battery,” is published online in Angewandte Chemie.

In rechargeable lithium-ion batteries, positive and negative electrodes comprise contiguous 2D nanosheets, often rolled up together like posters in a tube, and submerged in an electrolytic solvent. In commercial batteries the negative electrode (anode), which generates electric charge, is often made of a graphitic compound such as graphitic carbon nitride (g-C3N4), because of graphite’s low cost and high chemical stability (the positive electrode — or cathode — is often a metal oxide compound). The composition of the anode material is critical because it determines the cell voltage and capacity.

Taylor explained that while g-C3N4 nanosheets would seem an obvious candidate for sodium-ion batteries because of scalability and low cost, they exhibit poor electronic conductivity, low reversibility (of critical importance in rechargeable batteries), poor sodium-ion storage capacity, and insufficient cyclability.

“It is thought that the development of high-performance g-C3N4 based negative electrode materials could constitute important progress towards practical sodium-ion batteries,” said Weng.

The researchers found a workaround by altering g-C3N4 through a carbonization process in which a mixture of urea and asphalt are used as precursors, delivering a stacked multilayer graphitic carbon nitride-based compound.

“This altered compound, carbonized graphitic carbon nitride (C/g-C3N4), is not only chemically stable in sodium-ion batteries but also cost effective, since electrode sheets can be produced in large sheets at low cost,” explained Taylor.

When the team tested batteries using the altered anodes, they achieved two times higher sodium storage capacity for C/g-C3N4 compared to the untreated, pristine g-C3N4 counterpart. They also demonstrated that C/g-C3N4 can be combined with sodium rhodizonate dibasic (Na2C6O6) to create a high-capacity full cell with stable cycling (the process of fully charging and discharging a battery). The end result is a promising negative electrode material for developing low-cost and long-life sodium-ion batteries.

Further, the team’s process resulted in a battery with Coulombic efficiency — the ratio of the total charge extracted from the battery to the total charge put into the battery over a full cycle — of 99.8%, which is just a tenth of a percent below that of lithium-ion batteries.

“We showed here really negligible capacity fading over 14,000 testing cycles, and that’s really good metrics in the research lab,” said Taylor, adding that the C/g-C3N4 compound also demonstrated potential for high-rate capability — the ability of a battery to withstand rapidly charging and discharging electricity. “This capability is critical for both individual and industrial applications, including grid storage,” he said.

The team’s plan is to develop this material further with companies that may have an interest in working with them through the NYU Office of Industrial Liaison.

The paper, “A Promising Carbon/g‐C3N4 Composite Negative Electrode for a Long‐Life Sodium‐Ion Battery,” is available at: https://onlinelibrary.wiley.com/doi/full/10.1002/anie.201905803

This research was supported by the National Science Foundation and NSF-PECASE award, Tandon School of Engineering, and the Fondazione Oronzio e Niccolò De Nora Fellowship.

About the New York University Tandon School of Engineering

The NYU Tandon School of Engineering dates to 1854, the founding date for both the New York University School of Civil Engineering and Architecture and the Brooklyn Collegiate and Polytechnic Institute (widely known as Brooklyn Poly). A January 2014 merger created a comprehensive school of education and research in engineering and applied sciences, rooted in a tradition of invention and entrepreneurship and dedicated to furthering technology in service to society. In addition to its main location in Brooklyn, NYU Tandon collaborates with other schools within NYU, one of the country’s foremost private research universities, and is closely connected to engineering programs at NYU Abu Dhabi and NYU Shanghai. It operates Future Labs focused on start-up businesses in downtown Manhattan and Brooklyn and an award-winning online graduate program. For more information, visit http://engineering.nyu.edu.