Innovation Abounds at the Prototyping Fund Showcase

From a food computer to a tamper-resistant, timed-release pill bottle, over a dozen innovative student-built designs filled the MakerSpace at the Fall 2016 Prototyping Fund Showcase on December 6. The student teams, funded by the NYU Entrepreneurial Institute and Tandon’s Greenhouse, presented their prototypes that they’ve been tirelessly creating, revising, and building during the fall semester. Each semester the Institute, which fosters entrepreneurs and startups within the NYU community, and Greenhouse, a collaborative space that nurtures student ideas and projects, award teams comprised of students from Tandon and other NYU schools $500 to transform their ideas into prototypes. With designs in hand, many teams are seeking to make their ideas a commercial reality. Here’s a look at some of the innovative projects showcased:

Food Computer

Inspired by MIT’s food computer and evolving methods of urban farming, graduate students Jonas Günther MS ’18, Omar Gowayed PhD ’21, and Selim Senocak MS ’18 set out to build their own food computer design — a computer-controlled and self-enclosed environment that employs hydroponics, artificial light, and nutrient recipes to grow vegetables in urban spaces. The team created a small-scale system that features economical materials and two reservoirs, one for growing arugula and one for water and nutrients, which provide more precise measurements of nutrients before they’re delivered to the plants. After experimenting with light, pH balance, nutrient delivery and programming the microcontrollers, the next phase is making their product fully automatic. “Once it’s fully automatic,” Günther said, “we can decrease operating costs, increase efficiency, and make it more commercially viable.” Ensuring access to fresh produce is a larger objective of their project, as they’re hoping to develop a “cost-effective, environmentally-friendly, but productive way to grow food” without hormones or pesticides, Gowayed said. “This is a self-enclosed system that could either be an entire building, or it could be on someone’s desktop to grow food for themselves and for their community.”

Filament Maker

Someday soon, 3D printers may be as ubiquitous as the laser printer is now. Considering this fact, Dakota Marin BS ’19 and Roshaun Morris BS ’19 teamed up to build a machine that turns shredded recycled plastic — from water bottles to defective 3D-printed prototypes — into 3D printer filament. “This product is geared towards people who love getting their hands dirty,” Marin said, who envisioned the product while making filament for a 3D printer at NYU Dentistry’s Biomaterials lab. Marin and Morris’ product not only recycles plastic, but it will provide the consumer with an affordable add-on to their 3D printer. The Filament Maker works by melting shredded plastic and passing it through a needle-like tube to produce the thin, ready-to-use filament. While high-end 3D printers exist mainly in locations like Tandon’s MakerSpace and require specially-developed filament, more and more commercial printers may be entering people’s homes, Morris said. “Now is a good time to have an idea like this, where you can latch onto the evolution of the 3D printer.”

hümble

Combining technology with charity, the team behind hümble’s wearable charging device are focusing their business model on providing aid to the Syrian refugee crisis. Currently, the team will donate their profit from the charging device to an organization providing solar power stations in Syria, connecting their U.S. customer to the Syrian refugees. hümble’s wearable power source, fashioned to look like a bracelet or smartwatch, has two connections that allow the user to charge iPhone and Android phones through an LM cable, or charge the device itself. “In the long run, we’re going to expand our functions,” team member Kohtaro Kosugiyama BA ’20 (GLS) said, including creating personal alarms for Syrian women concerned about their physical safety. Currently, the hümble team — which includes Kosugiyama, Tandon students William Lee BA ’19 and Girish Ramloul BA ’19, as well as Mary Gao BA ’20 (Stern) and Christina Perry BA ’20 (Gallatin) — is hoping to work with investors towards building custom-made batteries, which would offer a “thinner and more appealing” design.

INVIP

Nicolas Metallo MS ’17, Nuvina Padukkavidana MS ’17, Brenda Truong MS ’17, Isabel Izquierdo MPH '17 (Columbia University), and Edson Tapia (University of Guadalajara, Mexico) focused their application INVIP on aiding visually-impaired individuals in navigating their surroundings, specifically within the university setting. INVIP uses iBeacon technology to determine the user’s location and their proximity to predefined locations, such as a department building or cafeteria, as well as provide an audio alert to help them navigate the campus. The team is currently working towards making INVIP an audio-visual assistant using Amazon’s Alexa and Microsoft Azure, that will take a picture of the user’s surroundings or a class-handout and describe the image or text to the user. Izquierdo explained that with simple questions, like “What’s in front of me, or describe the environment,” Alexa will be able to read aloud the INVIP user’s surroundings, providing a unique navigation feature missing from many applications for the visually-impaired.

Project Avocado’s NYU Freedge

The smart community sharing refrigerator, NYU FREEdge, developed out of Project Avocado’s Design for America project that aimed to reduce food waste and provide NYU students with access to free food. Project Avocado, comprised of Rodney Lobo MS ’17, Michael Miamehr BS ’19, Tuba Naziruddin MS '18, Vandit Maheshwari MS '18, Simon Chen BS '18 and Emma Hoffman BA ’18 (Gallatin), debuted a community refrigerator outside Tandon’s MakerSpace on November 29. Their design will eventually feature card-swipe access and a digital display for students to share or receive food. “If share is selected, the student will have to select from a list of options for the type(s) of food, and the type(s) of allergens,” Lobo said, “Students can share any kind of food, as long as it is still consumable.” The team hopes student dorms and NYU campus buildings will someday house NYU FREEdges to alleviate food insecurity and help to “build a stronger student community.”

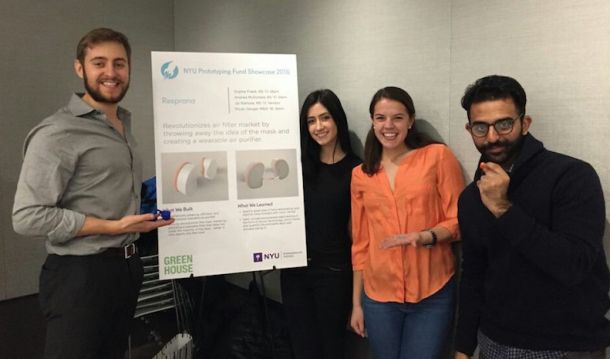

Resprana

Designed as an “innovative approach to the fight against urban air pollution,” Resprana’s Wearable Air Purifier aims to provide a minimalist breathing filter that removes “harmful volatile organic compounds and particulate matter from the air,” Micah Steiger MBA ’18 (Stern) said. With the dangerous air pollution and poor air quality increasing around the world, air-filtering face masks are becoming essential to everyday life. Yet, many people refuse to adopt face masks due to their “inhuman” quality, which prompted Resprana’s team of Steiger, Sophie Frank BS ’17 (Stern), Andrea McDonald BS ’17 (Stern), Jai Rathore MS ’17, and Sukanya Goswami MS ’16 to design a minimalist, in-nose device that allows the user to go about their daily lives, while also filtering harmful chemicals through nanofibers and a carbon filter. “We’ve been working with designers at the Pratt Institute to create a comfortable, easy to use product that is both universal in size and easy to clean and maintain,” Steiger said.

Service Drone

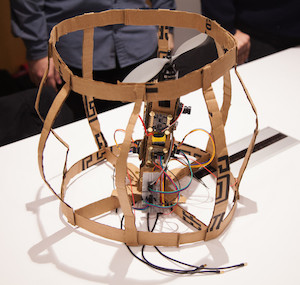

Thinking beyond a drone’s use for aerial photography or for delivering packages, Aidan Collins BS ’18, Kristin Moser BS ’18, Sevde Talubas BS ’18, and Lazarus Toshi BS ’18 — the students behind Service Drone — wanted to create a drone that could act as an assistant and companion to persons with disabilities, similar to a service dog. “We found out the process of getting a service dog is very time consuming and expensive,” Toshi said, which prompted the team to build a drone that could aid an individual by guidance, assisting with tasks, and ensuring their safety. Their design stores the graphics processing unit (GPU) offboard to perform external machine learning calculations, cutting back on weight and power drain. “Because of the role we intend the drone to have, we need it to have the longest battery life possible,” Toshi said.

Thinking beyond a drone’s use for aerial photography or for delivering packages, Aidan Collins BS ’18, Kristin Moser BS ’18, Sevde Talubas BS ’18, and Lazarus Toshi BS ’18 — the students behind Service Drone — wanted to create a drone that could act as an assistant and companion to persons with disabilities, similar to a service dog. “We found out the process of getting a service dog is very time consuming and expensive,” Toshi said, which prompted the team to build a drone that could aid an individual by guidance, assisting with tasks, and ensuring their safety. Their design stores the graphics processing unit (GPU) offboard to perform external machine learning calculations, cutting back on weight and power drain. “Because of the role we intend the drone to have, we need it to have the longest battery life possible,” Toshi said.

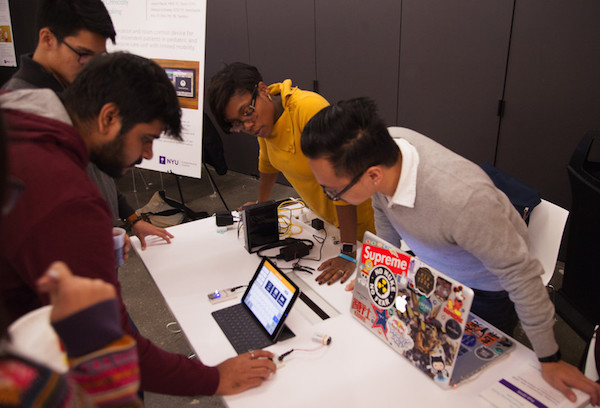

TECHnically Speaking

Mark Arroz MA ’17 (Steinhardt), Jason Beck MPS ’17 (Tisch ITP), Ifetayo Estrada OTD ’17 (Steinhardt), Yi-Wei Hsu MS ’18, Adisa Narula BA ’17 (CAS), and Yan Zhao MPS ’17 (Tisch ITP) designed the tablet application TECHnically Speaking during their Developing Assistive Technology course in NYU Steinhardt’s Occupational Therapy department. The project paired the students with NYU Langone’s Intensive Care Unit (ICU), which inspired the team to create an application that works towards better facilitating communication between medical personnel and ICU patients, many of whom have difficulty moving or speaking, or face language barriers. Using iPads, wifi, bluetooth, and a bluetooth-connected button, the application features a “Call Nurse” option that will alert the nurses’ station, as well as options to communicate through categories like “I Feel,” “I Need,” or “Pain,” in which patients can ask for water or describe the location and severity of their pain. Another function of the application is room control, where patients “can choose to change the lights or turn on the TV through the iPad,” Hsu explained. The team is working towards adding multiple language options to the application, as well as refining the technology to wirelessly connect the iPad to the hospital room. "We hope we can let the patient have more independence.”

Camila Ryder

Graduate School of Arts and Science

Master of Arts in English Literature, Class of 2018