Budding Researchers Impress at Research Expo's First Undergraduate Capstone Competition

For the first time, NYU Tandon School of Engineering's Research Expo featured a competition open to all undergraduate students participating in senior design or capstone courses. Students had the opportunity to impress judges with a five-minute elevator pitch on their project, along with a brief video presentation — and they did not disappoint.

Associate Professor Jin K. Montclare explained, “The purpose of the competition was to highlight our students’ abilities to innovate and make a tangible difference to society through their design or capstone projects as part of their courses, and provide them recognition for their hard earned work. We also provided them prizes to help them bring their prototypes to reality (through funds and resources) and possibly launch their own start-ups.” Prizes for the winning projects included $5,000, $3,000 and $1,000 for the first, second, and third place respectively. Winners also received interview spots for NYU’s Summer Launchpad program, as well as expert assistance to patent their work.

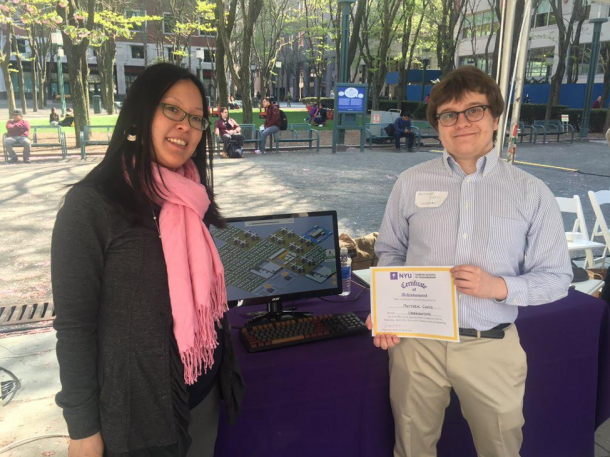

Associate Professor Jin Montclare (left) with first place winner Matthew Conto

Matthew Conto’s (Integrated Digital Media, Class of 2016) project “Urbanomino” (Urban + Dominoes) secured first place; the project explores how a city building game might function when different sets of people, like businesses and developers, have a stake in shaping their city. The game uses a voting system to introduce an element of organic unpredictability in the growth of a modern urban economy. Conto was inspired by his love for the game SimCity, although he observed that the game was not a democracy but rather a dictatorship. “Urbanomino explores the role of a modern urban planning committee and how cities are shaped not by dictators but by many other people trying to envision what they want in their city,” Conto explained.

Associate Professor Jin Montclare flanked by second place winners, Devorah Shira (left) and Meshal Alhathal

Project “MEG” by Meshal Alhathal (Electrical Engineering, Class of 2016) and Devorah Shira (Electrical and Computer Engineering, Class of 2017) won second place. A device that monitors physical exercises for in-home and clinic usage, MEG offers automated physical therapy sessions while maintaining their accuracy. The device will be helpful to Lymphedema patients, elderly, rehabilitation centers, and diabetics to guide them do in-home sessions correctly and be verified by their doctors, nurses, or physical therapists. Alhathal stated, “Being in the Capstone Competition truly showed me that my research will go beyond lab experiments to help people that need in-home physical therapy to improve the quality of life. With medical, entrepreneurial, and engineering collaboration, this is what makes my research experience at NYU Tandon unique.”

Third place winners (left to right): Avitosh Totaram, Shawon Rabidas, Steven Zeltmann, and William Peng with Associate Professor Jin Montclare (not pictured Sandy Shen and Matthew Lemanski)

Third place was secured by seniors Steven Zeltmann, Sandy Shen, Matthew Lemanski, Shawon Rabidas, Avitosh Totaram, and William Peng, for their additive and embedded manufacturing project “3DeltaWorks.” Inspired by a seminar on advanced additive manufacturing techniques, the team combined a 3D printer with a pick and place robot to streamline the process of creating functional parts. Currently, the process for manufacturing sensor-embedded devices can only be carried out by a specialized assembly line with multiple workstations for the printing and embedding steps. 3DeltaWorks addresses this challenge by combining an extruder nozzle and robotic actuators on a single printhead, shrinking all of the assembly lines into one lean, compact manufacturing robot. Zeltmann commented, “Viewers who were already familiar with 3D printing technology were surprised when we held up a sample printed part built by our machine, a cylinder with a mechanical component (a captive nut) firmly embedded inside. They would always invariably ask us in some form how we did that.”

Lathika Chandra Mouli

New York University Shanghai

B.S. in Electrical Engineering, Class of 2017