Evolution of Mechtronics as a Contemporary Design Paradigm

The industrial, semiconductor, and information revolutions have led to major technological advancements in the design and operation of engineering products.

Industrial Revolution

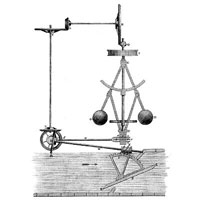

The industrial revolution enabled design of products and processes to convert and transmit ever-increasing amounts of energy for industrial activities. Engineering designs of this era performed operations of motion transmission, sensing, actuation, and computation using mechanical components e.g., cams, gears, levers, linkages, etc. Watt's flyball governor typifies the engineering designs of this era. Unfortunately, purely mechanical systems suffer from power amplification inability and energy losses due to tolerances, inertia, and friction (Tse and Morse, 1989).

Semiconductor Revolution

The semiconductor revolution leading to the development of integrated circuit (IC) technology created the next key impact on the design of engineering products. On the actuation side, through cost effective, miniaturized, power electronics for efficient power amplification, semiconductor technology provided a practical means of delivering required levels of power to mechanical devices via electrical means. Similarly, on the sensing side, semiconductor technology afforded an ability to condition and encode physical measurements as analog/digital signals. Furthermore, hardwired, onboard, analog/digital electronics provided rudimentary computational abilities to mechanical devices. Rapid developments in electro-mechanical sensing and actuation hardware, which had begun in an earlier era, further fueled the adoption of semiconductor technology in the design and operation of mechanical devices.

An Integrated Circuit Chip

Analog to Digital Converter

Operational Amplifier

Information Revolution

In the closing decades of 20th century, as the semiconductor and information technology industries experienced explosive growths, the computing hardware became ubiquitous and cheap. A momentous transformation in the design and operation of mechanical devices and systems began to unfold, with information technology emerging as a technology enabler imparting intelligence to numerous products, processes, and machines. Microprocessors began replacing precision mechanical components, e.g., precision-machined camshaft, which in many applications functions as a timing device. In addition, programmability of microprocessors provided a versatile and flexible alternative to the hardwired analog/digital computational hardware. Integrated computer-electrical-mechanical devices now became capable of converting, transmitting, and processing both the physical energy and the virtual energy (information). Thus, in recent years, engineers began developing highly efficient products and processes by judicious selection and integration of sensors, actuators, signal conditioning, power electronics, decision and control algorithms, and computer hardware and software.

Data Acquisition Board

Stamp microcontroller