Liquid Level and Flow Control Rig

Brief description:

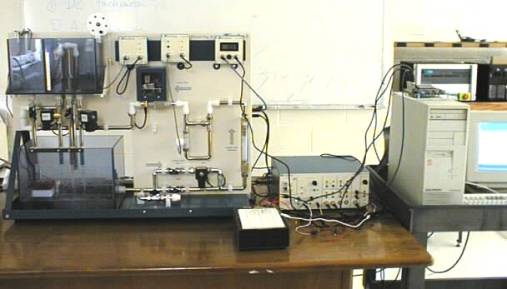

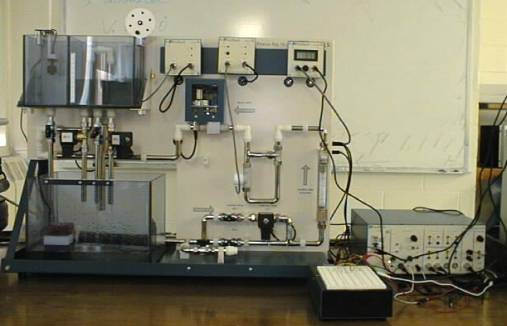

This experiment consists of a relay-controlled, submersible pump that lifts liquid from a lower tank through a piping network into an upper tank (see pictures below). The liquid from the upper tank is drained into the lower tank through several pipes that can be opened/closed by solenoid valves. A servo valve controls the liquid flow rate into the upper tank. The liquid flow rate is measured by a flow rate sensor while the liquid level in the upper tank is measured by a float sensor. The objective is to maintain a certain level of liquid in the upper tank.

Usage:

Undergraduate controls laboratory, design projects in graduate controls-oriented courses, and graduate student research.

Past experience:

The Feedback Inc. engineers have modified their standard process interface, per our specifications and recommendation, to provide an open architecture control environment that facilitates interfacing of process inputs and outputs to typical data acquisition and control cards (e.g., MultiQ3). Open-loop response data, system component calibration, differential on-off control, and PI control for liquid level set point regulation have been carried. This testbed is currently being used to investigate algorithms for system identification and nonlinear trajectory tracking control.

Future Plans:

Dynamic modeling, system identification, and linear/nonlinear control. Integration with a liquid temperature control rig.

Supplier:

Feedback Inc.

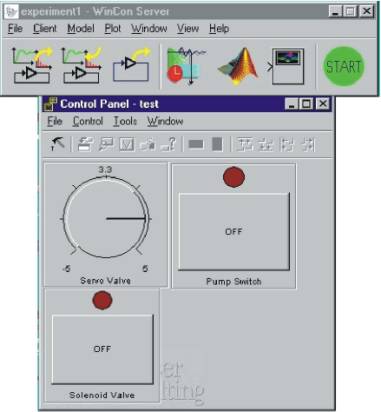

Wincon Server and Control Panel for Virtual Control: In this first simple test example, the control knob opens the servo valve, pump switch turns the pump on, solenoid valve switch turns the solenoid valve on.

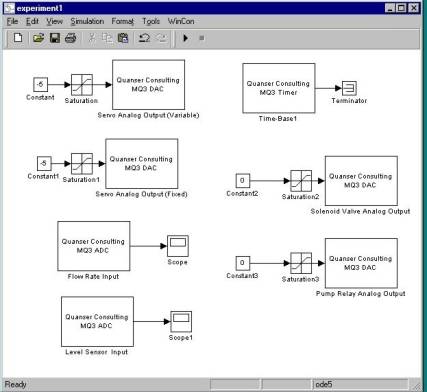

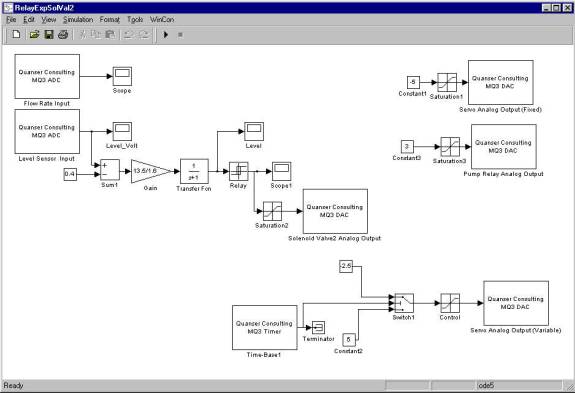

Simulink control diagram for open-loop control of servo valve, pump relay, and solenoid valve

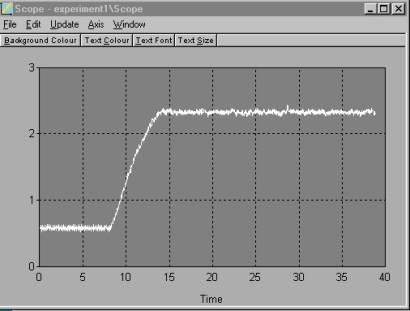

An illustrative response of the flow rate sensor when a step input is applied to the servo valve

Differential on-off control (relay control) for liquid level set point regulation

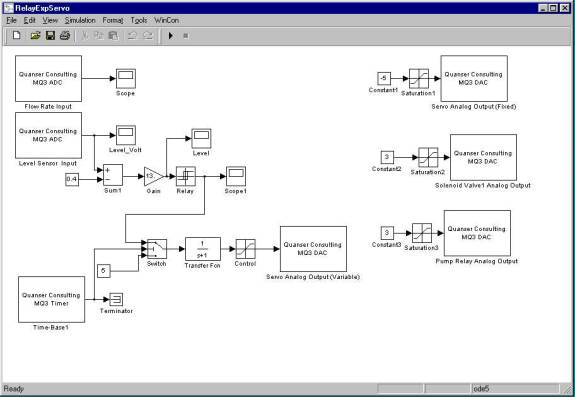

1. Servo-valve differential on-off control Simulink controller block-diagram

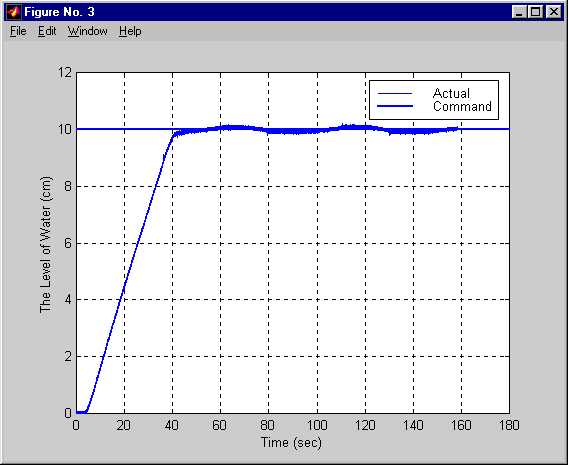

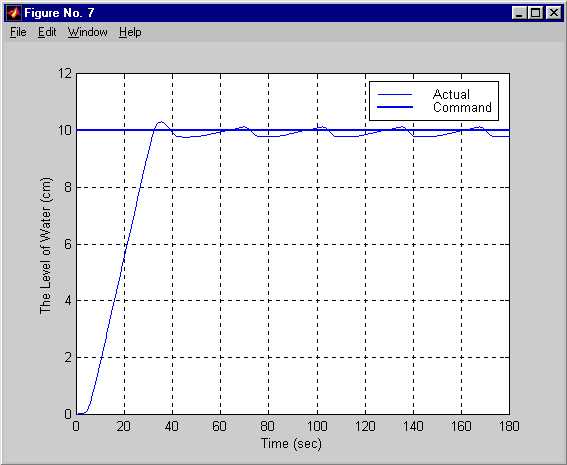

Liquid level response

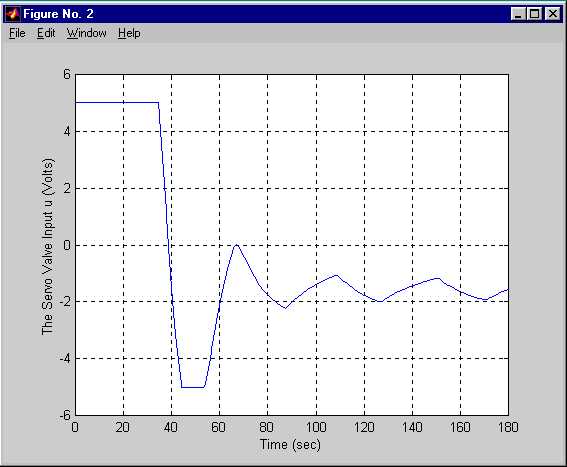

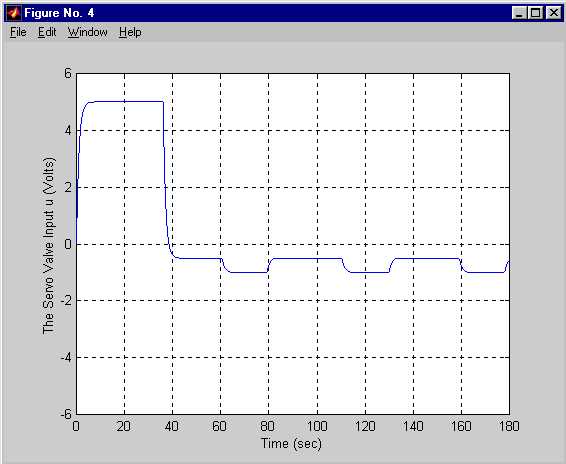

Servo valve control effort

2. Outflow solenoid valve differential on-off control Simulink controller block-diagram

Liquid level response

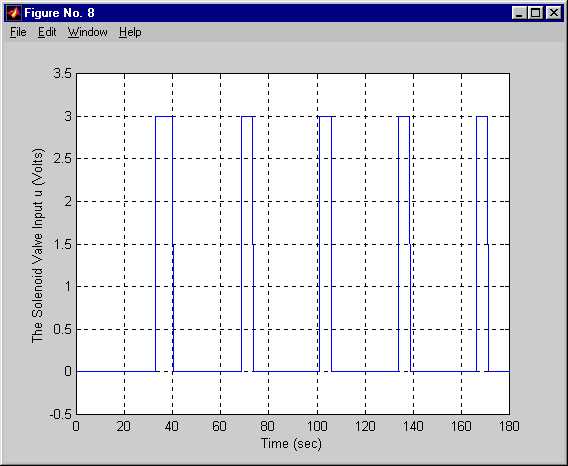

Solenoid valve control effort

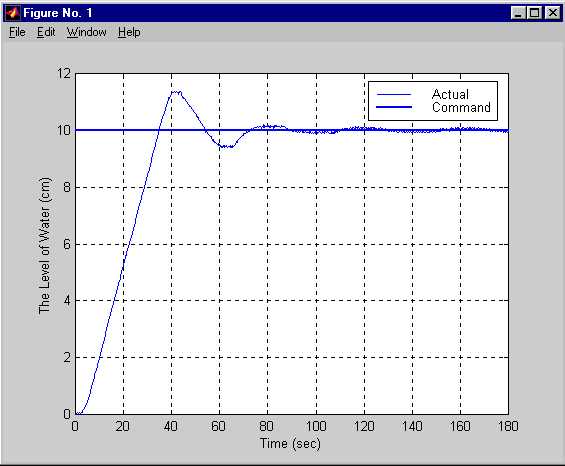

Proportinal plus integral control of servo valve for liquid level set point regulation

Simulink controller block-diagram

Liquid level response

Servo valve control effort