Using Yeast to Build a Better Plastic

NYU-Poly Chemist Uses Yeast, Plant Oils to Produce Super-Durable Recyclable Plastic; Next Step: Transforming It into Biofuel

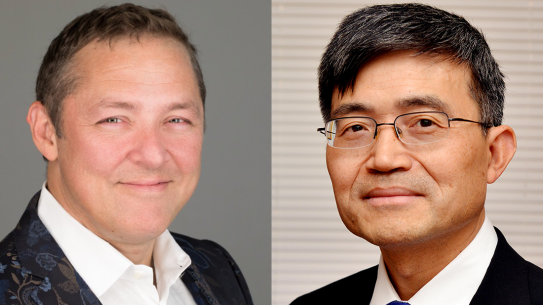

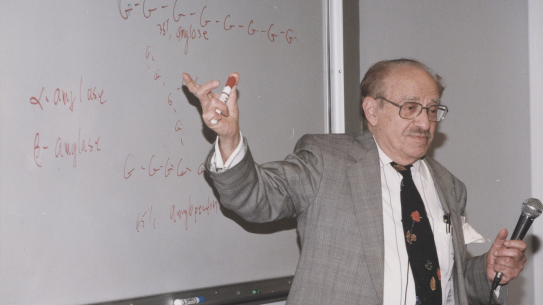

Dr. Richard Gross, professor of chemical and biological science at Polytechnic Institute of New York University (NYU-Poly), has developed a method for producing a strong, highly ductile bioplastic using yeast and one of nature’s simplest building blocks: fatty acids of plant oils. The findings were published in the Journal of the American Chemical Society.

Like all plastics, the new material is a polymer — a large molecule comprised of smaller, repeating units called monomers. In this case, the monomer itself is relatively new. The units are called omega-hydroxyfatty acids, and when strung together to form a polymer, they can produce a biologically friendly plastic. Until now, omega-hydroxyfatty acids were difficult and expensive to produce using traditional methods, prohibiting their widespread use.

Gross produced the monomer in a first-of-its-kind fermentation process, a fairly quick, low-cost method. The monomer is then polymerized to form a uniquely ductile, strong natural plastic that biodegrades completely in soil.

Gross and his team devised a new way to produce these monomers by using a genetically modified strain of Candida tropicalis, one of the many types of yeast that live harmlessly in humans and animals. The engineered yeast is capable of converting fatty acids of plant oils into large quantities of omega-hydroxyfatty acids. When polymerized, the new material may be a suitable substitute for petroleum derived plastics such as polyethylene for uses such as disposable gloves, multilayer food packaging films, and films for ice, trash, garments, produce bags and more.

“This is a very exciting development in the field, and not just because we’ve created a bioplastic with desirable properties,” said Gross. “This process uses no fossil fuels, and every step is biologically-friendly, from fatty acids in plant oils through the end product, which is a versatile, 100 percent biodegradable plastic.” The new bioplastic is highly resistant to moisture, which is an important improvement over currently sold bioplastics such as polylactic acid and starch-based plastics.

Gross’ company, SyntheZyme, was tapped by the U.S. Defense Advanced Research Projects Agency (DARPA) to develop this bioplastic. The material was originally intended to serve a dual purpose: as packaging material in the solid state, and as a biodiesel for military engines after being broken back down or de-polymerized to monomer units. The material development and performance in the solid state has been successfully completed; research into converting the plastic to diesel is currently under way. SyntheZyme is a member of the New York City Accelerator for a Clean and Renewable Economy (NYC ACRE), a new-business accelerator for clean technology and renewable energy companies in New York City. Based in the first New York City-sponsored business incubator, at 160 Varick Street, NYC ACRE is operated by NYU-Poly as part of its commitment to invention, innovation and entrepreneurship – a philosophy it calls i-squared-e – and receives support from New York State Energy Research and Development Authority (NYSERDA).

Note to Editors: Download images here.

About Polytechnic Institute of New York University

Polytechnic Institute of New York University (formerly Polytechnic University), an affiliate of New York University, is a comprehensive school of engineering, applied sciences, technology and research, and is rooted in a 156-year tradition of invention, innovation and entrepreneurship: i2e. The institution, founded in 1854, is the nation’s second-oldest private engineering school. In addition to its main campus in New York City at MetroTech Center in downtown Brooklyn, it also offers programs at sites throughout the region and around the globe. Globally, NYU-Poly has programs in Israel, China and is an integral part of NYU's campus in Abu Dhabi.