Methodology

The chassis was made with a

circular base with platforms for extra components such as infrared sensors, the

holding tank for the polyurethane, and the polyurethane dispenser attached to

the back of the robot. The wheels were aligned similar to the boe-bot chassis made by Parallax Co, with two wheels

attached to servo motors in the front and a ball type wheel in the back for

support.

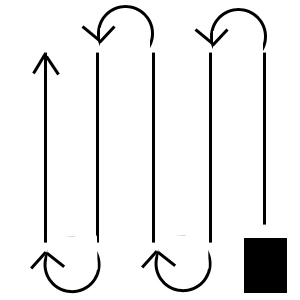

The programming of the robot involved using

infrared sensors to detect obstacles and walls while moving the robot in a row

by row pattern to ensure a good polish job (fig.1). The challenge exists mainly

in getting every square inch covered, because as the robot turns, it left a

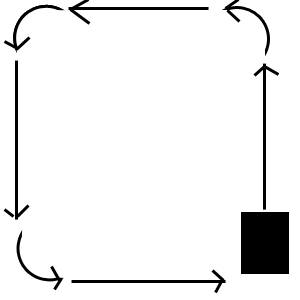

little wedge uncovered. So the robot was first programmed to implement a wall

following program to cover up the missed edges (fig.2).

Fig.1 180 degree turns, Area cover program

Fig.2 90 degree turns, Wall-follow program

To test an autonomous robot, it would make

sense to have obstacles; however, because the robot is a floor polisher,

circumstances had to be considered: all movable furniture were

removed from area prior to polishing even when people were manually applying

the polyurethane. So basically the only obstacles needed to be avoided were the

walls and maybe some occasional poles and steps. Because the test model was

small, the area for testing was also reduced to a topless box-type arena with few

obstacles. Since using actual polyurethane is expensive and hazardous, caro syrup, a liquid of similar viscosity, was used to

mimic polyurethane.