Discussion

Despite the seemingly

simplistic needs of the robot, the design and the parts require a lot more

attention. First the tank had been placed in the front to offset the weight

provided by the roller; however, this proved to be dangerous as water would be

traveling above the circuitry. Therefore, all of the circuitry was placed in

the front on two tiers: one for the breadboards and one for the

microcontroller. The tank was also connected to a solid instead of a flexible

pipe that rotates on the same center point as the roller. Unfortunately, the

roller attachment had to be slightly off-center in order to line up the roller

with the robot. This disrupted the symmetry between the two turns, requiring

different adjustments.

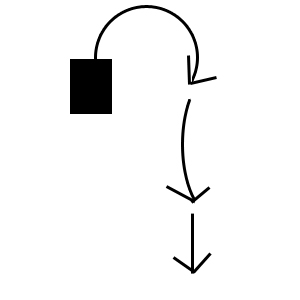

?Another challenge was getting

the robot to turn precisely 180 degrees and 90 degrees and go straight

afterwards. Not only were the servo motors that were being used temperamental

and refused to go straight in the first place, but also the roller attachment

ultimately dragged and forced the robot to drift to the side of the roller. Hence

an S-turn was applied to the program to straighten the roller by dragging it

further into a turn [fig.3]. However, several design flaws prevented constant

results from occurring; one was the rotating back wheel, which created

unpredictable turns; another was the offset roller position, which created

uneven drags on the two sides.

?In the future the several

design flaws discussed previously will need to be fixed in order to refine the

turning. Also, the servo motors must be replaced with dc motors because more

power may be needed to pull the roller along with the liquid. A centered roller

attachment along with the back corners cut to prevent the roller from getting

caught on the corners is necessary.

?

Fig.3 S-turn for 180 degrees