|

Mechanical System Modeling

The

equations of motion involving a rotary flexible link, involves

modeling the rotational base and the flexible link as rigid

bodies. As a simplification to the partial differential equation

describing the motion of a flexible link, a lumped single degree

of freedom approximation is used. We first start the derivation

of the dynamic model by computing various rotational moment

of inertia terms. The rotational inertia for a flexible link

and a light source attachment is given respectively by

|

|

|

(1)

(2)

|

where

mlink is the total mass of the flexible link,

mlight is the mass of the light source compartment,

and L is the total flexible link length. Combining the

moment of inertia�s for both the link and the light source gives

|

|

|

(3)

|

For

a single degree of freedom system, the natural frequency is

related with torsional stiffness and rotational inertia in the

following manner

|

|

|

(4)

|

where

w n is found experimentally

and Kstiff is an equivalent torsion spring

constant as delineated through the following figure

In

addition, any frictional damping effects between the rotary

base and the flexible link are assumed negligible. Next, we

derive the generalized dynamic equation for the tip and base

dynamics using Lagrange�s energy equations in terms of a set

of generalized variables a and q,

where a is the angle of tip deflection

and q is the base rotation given

in the following

|

|

|

(5)

(6)

|

where

T is the total kinetic energy of the system, P is

the total potential energy of the system, and Qi is

the ith generalized force within the ith

degree of freedom. Kinetic energy of the the base and the flexible

link are given respectively as

|

|

|

(7)

(8)

|

The total kinetic energy of the mechanical system

is computed as the sum of (7) and (8)

|

|

|

(9)

|

Potential energy of the system provided by the

torsional spring given as

|

|

|

(10)

|

Applying equation (9) and (10) into (5) and

(6) results in the following dynamic equations

|

|

|

(11)

(12)

|

Next

we compute the amount of virtual work, W, applied into

the system. The amount of virtual work is given to be

|

|

|

(13)

|

where t is

the torque applied to the rotational base. Rewriting equation

(13) into a general form of virtual work given as

|

|

|

(14)

|

We

obtain the virtual forces applied onto the generalized coordinatesQq

and Qa , respectively

to be

|

|

|

(15)

(16)

|

After

decoupling the acceleration terms of (11) and (12), the dynamic

equations for the mechanical subsystem are

|

|

|

(17)

(18)

|

Next, rewriting equations (17) and (18) into

a state space form gives

|

|

|

(19)

|

Electrical System Modeling

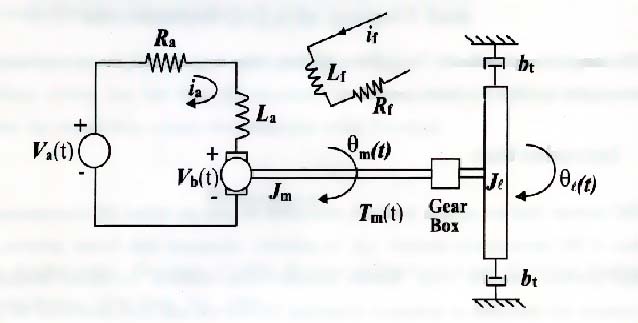

Since

the control input into the mechanical model of equation (19)

is a torque t , an electrical dynamic

equation relating voltage to torque is needed. First, the torque

applied to the rotational base, on the right hand side of equation

(19), is converted to the torque applied to the gear train by

the DC servomotor by means of a gear ratio Kg

given as

|

|

|

(20)

|

where

t m is the torque

applied by the servomotor. Next, the circuitry within the DC

motor system consists of a resistor, an inductor, an external

voltage source, and a back emf placed in a series circuit. The

following figure describes the circuit as previously described

Applying

Kirchoff�s voltage law to the above figure, produces

|

|

|

(21)

|

where I is the current in the circuit,

R is the resistor, L is the inductor, Vb

is the back emf, and VPC is the voltage supplied

by the data acquisition board. The DC servomotor is an electromechanical

device that relates torque to current through a proportionality

gain KT given in the following equation

|

|

|

(22)

|

In

addition, the back emf is a voltage applied by the motor shaft

to the circuit, which is directly proportional to the angular

velocity of the motor

|

|

|

(23)

|

where

Kb is the back emf constant and w

m is the angular velocity of the motor. Relating

the motor angular velocity with the base angular velocity gives

|

|

|

(24)

|

Substituting equations (22) and (24) into (21)

gives

|

|

|

(25)

|

Since

the effect of the inductance in the circuit is relatively small

in comparison with other circuit components, the derivative

term of torque can be neglected eliminated to give the following

approximate proportionality equation between voltage to torque

and angular velocity

|

|

|

(26)

|

The torque applied by the motor is solved for

in equation (26) to be

|

|

|

(27)

|

As

a result, the state space model of (19) can be rewritten to

utilize an electrical control voltage in (20) and (27) to give

|

|

|

(28)

|

Next,

a transformation between relative angular position and relative

displacement about a neutral axis is used within the state space

model of (28). The relative angular position, velocity with

respect to the rotating base is proportional to the relative

displacement, velocity of the flexible link tip (i.e. sin(a)�a)

|

|

|

(29)

(30)

|

The following figure shows the relationship

of these three parameters.

Substituting

the above equations of (29) and (30) into the state space dynamics

of (28) gives the following state space equation

|

|

|

(31)

|

Control Objective

The

objective for the rotary flexible link dynamic system is to

achieve an asymptotically stable system response for flexible

link. A Linear Quadratic Regulator (LQR) based controller achieves

asymptotic stable response for a controllable state space model.

For the state variable of d(t), an LQR controller drives

the flexible dynamic response to zero asymptotically. However,

for the angular position tracking of  a

new state variable is required to allow for setpoint tracking.

To achieve error regulation for a

new state variable is required to allow for setpoint tracking.

To achieve error regulation for  an angular displacement error and an angular velocity error

term is defined respectively as

an angular displacement error and an angular velocity error

term is defined respectively as

|

|

|

(32)

(33)

|

where

is a desired constant angular position for the flexible link.

In addition, an integral controller coupled in the rigid body

dynamics is defined within the state space dynamics of (31)

is a desired constant angular position for the flexible link.

In addition, an integral controller coupled in the rigid body

dynamics is defined within the state space dynamics of (31)

|

|

|

(34)

|

so that the state space dynamics of (31) is

augmented with (34) to give the following model

|

|

|

(35)

|

As

a result, the continuous time state space equation of (35) is

converted numerically into a discrete time state space equation

using Matlab. The resulting discrete time dynamic model is

|

|

|

(36)

|

Controller Design

Given

a 5th order system given in equation (36), the control

objective involves error regulation for the absolute angular

displacement of the rotary base and vibration control for the

end of the flexible link. A full state feedback control law

given by

|

|

|

(37)

|

where K Î

1�

5 such that the full state feedback control law of (37)

satisfies the following criteria

-

The closed loop state space system is

asymptotically stable

-

The performance functional given by

|

|

|

(38)

|

where

are

the state vectors and control inputs, respectively. The performance

functional of equation (38) regulates the state trajectories

of x(k) close to the origin without excessive control

demand through the design of the penalty weights of Q and

R. The nonnegative definite matrix Q Î

5�

5, determines the weight placed on each component of state.

The nonnegative definite matrix R Î

1 determines

the weight placed on the control input. The state feedback control

law given in (37) is computed through the following matrix equation are

the state vectors and control inputs, respectively. The performance

functional of equation (38) regulates the state trajectories

of x(k) close to the origin without excessive control

demand through the design of the penalty weights of Q and

R. The nonnegative definite matrix Q Î

5�

5, determines the weight placed on each component of state.

The nonnegative definite matrix R Î

1 determines

the weight placed on the control input. The state feedback control

law given in (37) is computed through the following matrix equation

|

|

|

(39)

|

where R2a and Pa

are defined as

|

|

|

(40)

|

such that the nonnegative definite matrix P

solves the following Ricatti equation

|

|

|

(41)

|

The computation of equation (37) is performed

numerically using Matlab resulting in the following set of state

feedback control gains:

|

|

Control Gains

|

|

|

K1 (V/deg)

|

K2 (V/cm)

|

K3 (V/deg)

|

K4 (V/cm)

|

K5 (V/deg)

|

|

0.2874

|

-0.8115

|

0.0516

|

-0.0017

|

0.1169

|

Experimental Setup

Matlab Controller Design

To

implement the Linear Quadratic Regulator, various system parameters

need to be defined. The following m-file provides all known

system parameters for use in Matlab: Parameters.m

In

addition, the state space matrix equation of (35) is defined

to compute the LQR gains for block diagram implementation. Two

first order noise and derivative filters are designed by specifying

a cutoff frequency. The m-file involves designing the filters

first in the continuous domain using Laplace transfer functions

and converting the continuous filters to the discrete domain.

The following m-files compute the state space model in addition

with the state feedback controller gains and digital filters

used in the experiment:

Model.m

Controller.m

The

implementation of the state feedback controller is performed

using a Simulink block diagram instead of manual C code generation.

Consequently, Simulink controller design compiles the block

diagrams into C code for hardware use. The following figure

shows the Simulink block diagram for the flexible link full

state feedback controller:

The

summing block in the previous figure gives the full voltage

control input into the rotary flexible link motor to be converted

into torque. The saturation block in the above figure is added

to prevent voltage overflow into the data acquisition board

(only capable of inputting and outputting �

5 volts). Also, the following Simulink block diagram defines

the subsystem of "System Sensor Inputs":

The

discrete derivative and noise filters for the encoder and camera

inputs are utilized through a continuous transfer function design

for a specified cutoff frequency integrated into a discrete

time transfer function model. An encoder calibration is utilized

to converted voltage to degrees from the encoder signal. The

camera input is converted from voltage to centimeters through

an experimental calibration gain. The "Output Control Voltage"

subsystem is given to be:

The "Conversion to Error" subsystem is defined

as:

|